Remove ads by Supporting Independent News

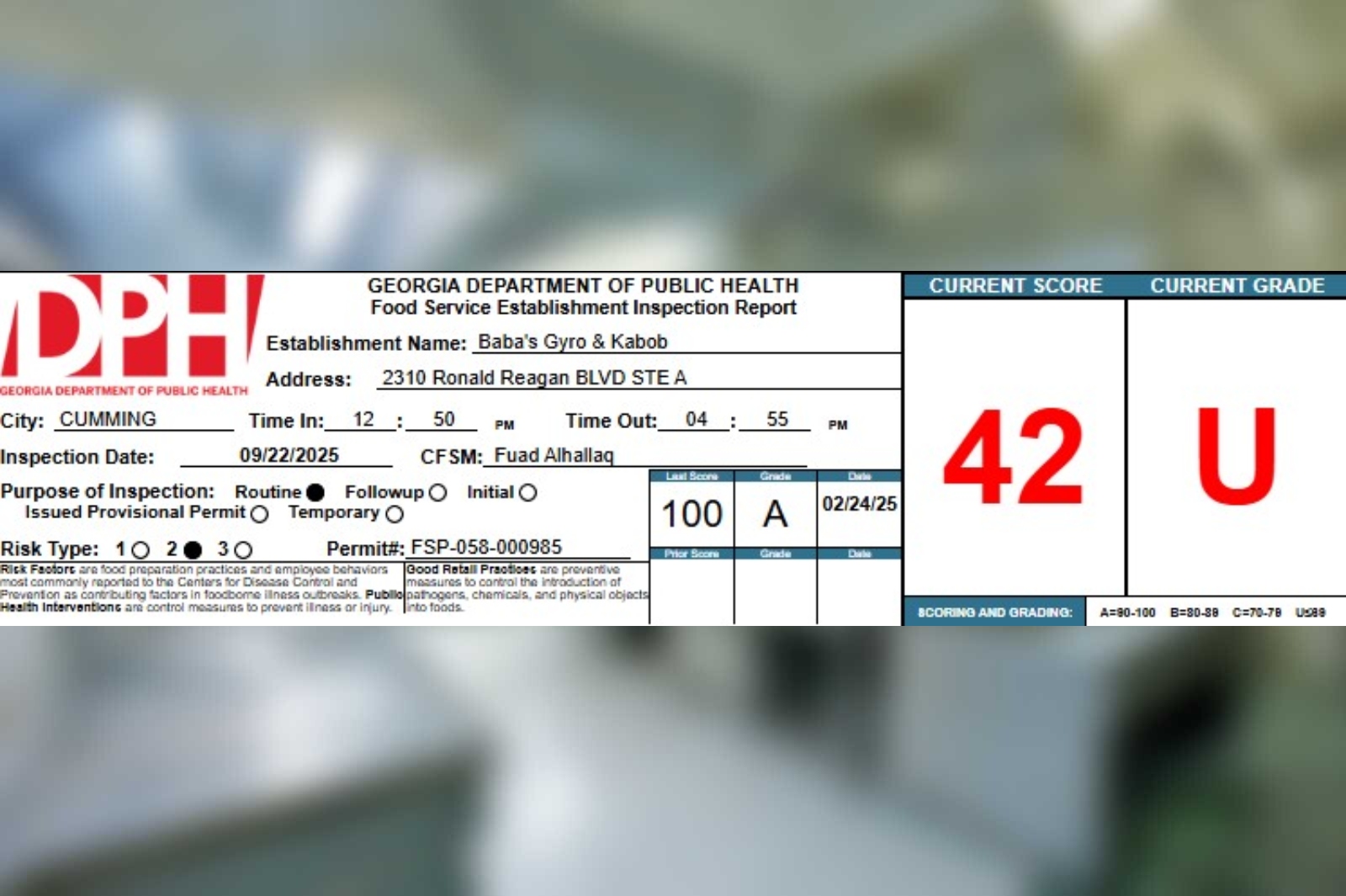

Baba’s Gyro & Kabob, located at 2310 Ronald Reagan Blvd Ste A in Cumming, received a score of 42 points out of a possible 100 points during their 09/22/2025 inspection by the Georgia Department of Public Health.

The violations noted by the inspector were:

Violation #1:

1-2A – pic present, demonstrates knowledge, performs duties

511-6-1.03(2)(a)-(n)(p),(q) – responsibility of pic (pf)

Points: 4

Corrected during inspection?: No

Repeat: No

Inspector Notes: Inspector observed Active Managerial Control measures not satisfactory for establishment to be in compliance with code. Corrective Action: Persons in charge, managers or CFSM must be properly trained or retrained.

Violation #2:

2-1B – hands clean and properly washed

511-6-1.03(5)(c) – when to wash (p)

Points: 9

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Inspector observed employee touching fan with gloved hand and then handling food/food equipment without removing gloves, washing hands, and donning new gloves. Inspector also observed employee putting his gloved hand in his pocket and then initiating a task that involves working with food without removing gloves, washing hands, and donning new gloves beforehand. COS- Employee removed gloves, washed hands, and donned new gloves after both observations. Corrective Action: Food employees shall clean their hands and exposed portions of their arms before donning gloves to initiate a task that involves working with food and after engaging in other activities that contaminate the hands.

Violation #3:

2-2D – adequate handwashing facilities supplied & accessible

511-6-1.06(2)(c) – handwashing sinks, installation (pf, c)

Points: 4

Corrected during inspection?: No

Repeat: No

Inspector Notes: Inspector observed women’s restroom handwashing sink water at 79F and men’s restroom handwashing sink water at 77F. Corrective Action: A handwashing sink shall be equipped to provide tempered water at a temperature of at least 85ºF (29.4 ºC) through a mixing valve or combination faucet.

Violation #4:

2-2D – adequate handwashing facilities supplied & accessible

511-6-1.06(2)(o) – using a handwashing sink- operation & maintenance (pf)

Points: 4

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Inspector observed drink pitcher inside of the bar handwashing sink. COS-relocated pitcher. Corrective Action: A handwashing facility may not be used for purposes other than handwashing.

Violation #5:

4-1A – food separated and protected

511-6-1.04(4)(c)1(i)(ii)(iii)(v)(vi)(vii)(viii) – packaged & unpackaged food separation, packaging, and segregation (p, c)

Points: 9

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Inspector observed prepped (then frozen) chicken stored above beef in reach in freezer. Inspector also observed raw chicken stored above beef and lamb in the walk in cooler. COS-re-located foods. Corrective Action: Food shall be protected from cross contamination by separating types of raw animal foods from each other such as beef, fish, lamb, pork, and poultry during storage, preparation, holding, and display.

Violation #6:

4-2A – food stored covered

511-6-1.04(4)(c)1(iv) – packaged & unpackaged food, food stored covered(c)

Points: 4

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Inspector observed cold-held food in the walk-in cooler without a cover. COS-added a cover. Corrective Action: store the food in packages, covered containers, or wrappings.

Violation #7:

6-1A – proper cold holding temperatures

511-6-1.04(6)(f) – time/temperature control for safety; cold holding (p)

Points: 9

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Inspector observed multiple TCS foods with temperatures >41F. COS-discarded foods. Corrective Action: time/temperature control for safety food shall be maintained at 41°F (5°C) or below.

Violation #8:

6-2 – proper date marking and disposition

511-6-1.04(6)(g) – ready-to-eat time/temperature control for safety food, date marking (pf)

Points: 4

Corrected during inspection?: No

Repeat: No

Inspector Notes: Inspector observed refrigerated foods in cooler that were prepped/opened >24 hours ago without date marking. Will return to facility in 48-72 hours to evaluate PIC’s date marking system. Corrective Action: refrigerated, ready-to-eat, time/temperature control for safety food prepared and packaged by a food processing plant shall be clearly marked, at the time the original container is opened in a food service establishment and if the food is held for more than 24 hours, to indicate the date or day by which the food shall be consumed on the premises, sold, or discarded, when held at a temperature of 41°F (5°C) or below for a maximum of 7 days after the original container is opened. The day the original container is opened in the food service establishment shall be counted as Day 1, except, the day or date marked by the food service establishment may not exceed a manufacturer’s use by date if the manufacturer determined the use-by date based on food safety

Violation #9:

8-2B – toxic substances properly identified, stored, used

511-6-1.07(6)(q) – first-aid supplies, storage (p, pf)

Points: 4

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Inspector observed burn gel located on same shelf as single service and cooking utensils. COS-relocated burn gel. First-aid supplies that are in a food service establishment for the employee’s use shall be: stored in a kit or a container that is located to prevent the contamination of food, equipment, utensils, and linens, and single-service and single-use articles.

Violation #10:

10D – food properly labeled; original container

511-6-1.04(7)(d) – other forms of information (c)

Points: 3

Corrected during inspection?: No

Repeat: No

Inspector Notes: Inspector did not observe written consumer allergen notification. PIC states that he informs customers verbally about major food allergens as an ingredient in unpackaged food items. Corrective Action: The permit holder shall notify consumers by written notification of the presence of major food allergens as an ingredient in unpackaged food items that are served or sold to the consumer.

Violation #11:

14A – in-use utensils: properly stored

511-6-1.04(4)(k) – in-use utensils, between-use storage (c)

Points: 1

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Inspector observed scoop handle sitting inside of a food container and touching the food. COS: Re-positioned scoop so handle is not touching the food. Inspector also observed a cup (without a handle) sitting inside of a food container and touching food. Corrective Action: During pauses in food preparation or dispensing, food preparation and dispensing utensils shall be stored in food that is not time/temperature control for safety food with their handles above the top of the food within containers or equipment that can be closed, such as bins of sugar, flour, or cinnamon.

Violation #12:

14B – utensils, equipment and linens: properly stored, dried, handled

511-6-1.05(10)(e)1,2,4 – equipment, utensil, linens, stored 6″ off floor in clean, dry location (c)

Points: 1

Corrected during inspection?: No

Repeat: No

Inspector Notes: Inspector observed wet-stacking/wet-nesting of containers. Corrective Action: Clean equipment and utensils shall be stored in a self-draining position that allows air drying.

Violation #13:

15A – food and nonfood-contact surfaces cleanable, properly designed, constructed, and used

511-6-1.05(1)(i) – nonfood-contact surfaces (c)

Points: 1

Corrected during inspection?: No

Repeat: No

Inspector Notes: Inspector observed wood in the freezer (used to have food sitting on top of it) that had an accumulation of a mold-like substance and moisture. COS-removed wood. Corrective Action: Nonfood-contact surfaces of equipment that are exposed to splash, spillage, or other food soiling or that require frequent cleaning shall be constructed of a corrosion-resistant, nonabsorbent, and smooth material.

Violation #14:

15A – food and nonfood-contact surfaces cleanable, properly designed, constructed, and used

511-6-1.05(1)(i) – nonfood-contact surfaces (c)

Points: 1

Corrected during inspection?: No

Repeat: No

Inspector Notes: Inspector observed foil liner under equipment in dry storage and on the shelves in the walk-in cooler. Corrective Action: Nonfood-contact surfaces of equipment that are exposed to splash, spillage, or other food soiling or that require frequent cleaning shall be constructed of a corrosion-resistant, nonabsorbent, and smooth material.

Violation #15:

16B – plumbing installed; proper backflow devices

511-6-1.06(2)(r) – system maintained in good repair (p, c)

Points: 2

Corrected during inspection?: No

Repeat: No

Inspector Notes: Inspector observed exterior septic system risers without screws. Inspector was able to easily lift/remove the riser lids without resistance. Corrective Action: A plumbing system shall be repaired according to law and maintained in good repair.

Violation #16:

17D – adequate ventilation and lighting; designated areas used

511-6-1.07(3)(h) – dressing areas and lockers, designated and provided (c)

Points: 1

Corrected during inspection?: No

Repeat: No

Inspector Notes: Inspector observed “crystal light” and “water bottle” placed on the prep top. COS-relocated. Corrective Action: Lockers or other suitable facilities shall be provided and used for the orderly storage of employees’ clothing and other possessions.

Violation #17:

18 – insects, rodents, and animals not present

511-6-1.07(2)(m) – outer openings protected (c)

Points: 3

Corrected during inspection?: No

Repeat: No

Inspector Notes: Inspector observed light gap at the rear screen door. Corrective Action: outer openings of a food service establishment shall be protected against the entry of insects and rodents by filling or closing holes and other gaps along floors, walls, and ceilings and by solid, self-closing, tight-fitting doors.

Additional remarks:

Dining room sani spray 300 ppm QAC. Dish machine sanitizer 50-100 ppm Cl at 108F at plate level. 4 compartment 100 ppm Cl at 115F. Completed Georgia NEARS Field Report with Ashley Wright. Performed inspection with Ashley Wright.

CLICK HERE to read the full report