Remove ads by Supporting Independent News

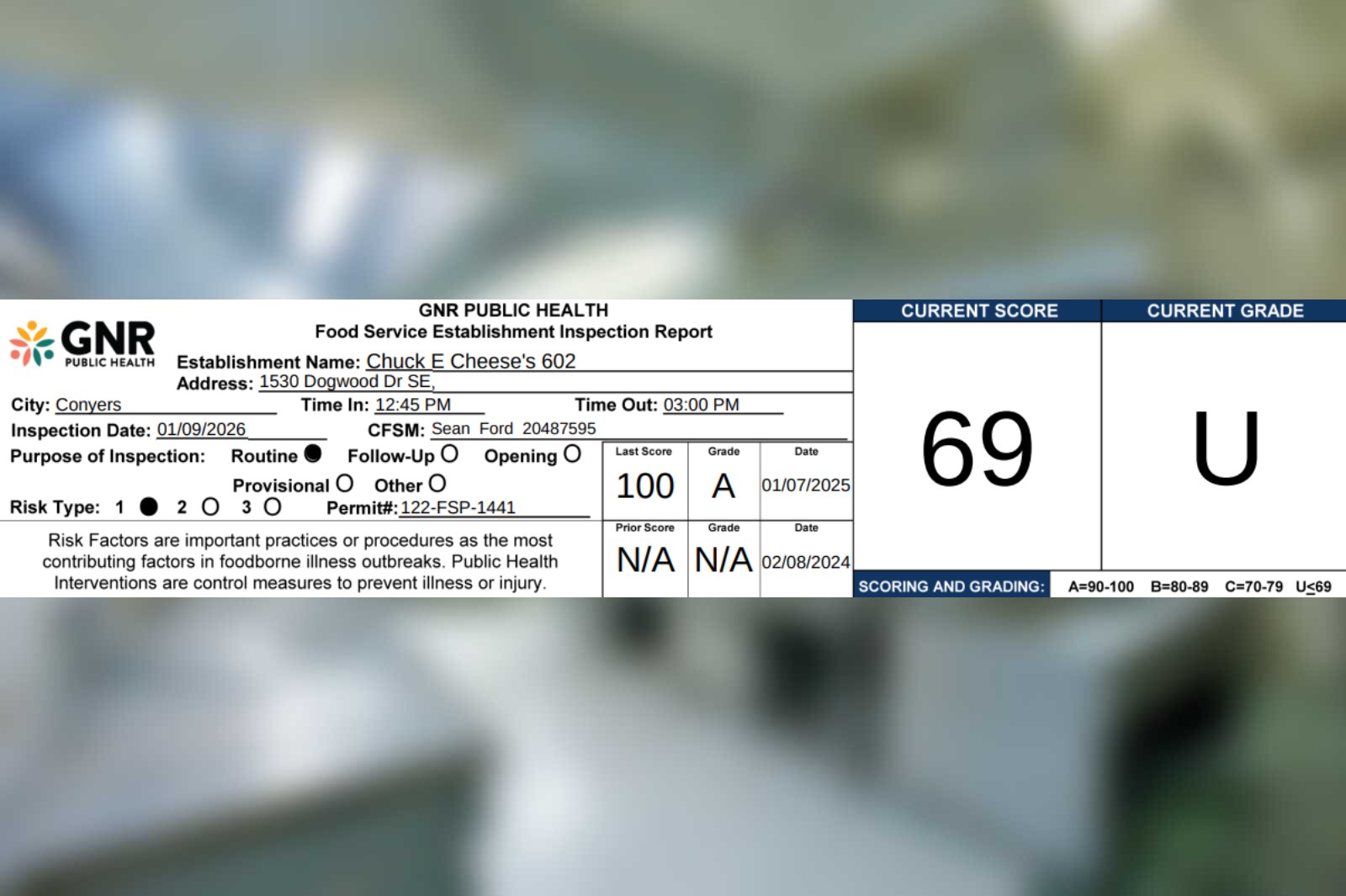

Chuck E Cheese’s, located at 1530 Dogwood Dr SE in Conyers, received a score of 69 points out of a possible 100 points during their 01/09/2026 inspection by the Georgia Department of Public Health.

The violations noted by the inspector were:

Violation #1:

1-2A: .03(2)(a)-(l), (n)Observed PIC (persons in charge) were unable to provide a key drop agreement. The business entity providing key drop deliveries to the establishment shall certify in writing to the establishment that the products delivered will be under its control throughout the delivery process to the establishment, and that all products will be delivered to the establishment during the key drop delivery hours pursuant to the secured access arrangement set by the food service establishment. (Pf)

Violation #2:

1-2A: .03(2)(a)-(l), (n)PIC did not have active managerial control; observed multiple violations during inspection. It is the responsibility of the person in charge to ensure compliance with the food code by demonstrating active managerial control within their facility. (Pf)

Violation #3:

2-1B: .03(5)(c)Observed while wearing gloves, food employee drop a pizza pan, remove her gloves, and went to the dish machine area. The food employee then touched a clean pizza cutter and went to prep cooler across the storage area and handled spices in metal utensil containers. Employees must wash hands and exposed portions of arms immediately before engaging in food preparation including working with exposed food, clean equipment and utensils, and unwrapped single-service articles, and: 1) after touching exposed body parts; 2) after using the restroom; 3) after coughing, sneezing, using tobacco, eating, or drinking; 4) after handling soiled equipment or utensils; 5) during food preparation, as often as needed to remove soil and contamination and to prevent cross contamination when changing tasks; 6) before putting on gloves; 7) after engaging in other activities that contaminate hands; 8) a second time when entering the kitchen from using the restroom. (P)

Corrective Actions: Food employee washed her hands. Pizza cutter was removed to the dish machine area to be rewashed.

Violation #4:

2-2D: .07(3)(b)At the beginning of the inspection, observed hand sink located by the reach-in-cooler did not have any hand paper towels. Handsink is the only hand sink in the kitchen. Each handwashing sink shall be provided with individual, disposable towels, a continuous towel system that supplies the user with a clean towel, or a hand drying device. (Pf)

Corrective Actions: Food employee placed hand paper towel by the hand washing sink.

Violation #5:

6-1A: .04(6)(f)Observed the following foods were cold holding above 41F in the prep cooler located by the oven. 1. pizza sauce 2. two bags of peperoni 3. shredded cheese 4. chopped chicken 5. ham 6. sausages 7. mozzarella cheese 8. a container of precooked chicken Prep cooler held ambient air of 38.0F. Observed spinach cold holding above 41F in the salad bar area. Time/temperature control for safety food shall be maintained at 41°F (5°C) or below. (P)

Corrective Actions: PIC had all foods discarded.

Violation #6:

4-1A – food separated and protected

12B: .03(5)(g)Observed a food employee shredding cheese while wearing two bracelets. Observed another food employee handing pizza dough while wearing two scrunchies on her wrist. Food employees may not wear jewelry including medical information jewelry on their arms and hands while preparing food (except for a plain ring such as a wedding band). (C)

Corrective Actions: Food employee only took off one of her bracelets. Food employee removed her two scrunchies

Violation #7:

15C: .05(7)(a)2,3Observed a storage rack in the walk-in-cooler had food debris. Observed a rolling cart with food debris. Rolling cart was located across the salad bar. Nonfood-contact surfaces of equipment shall be kept free of an accumulation of dust, dirt, food residue, and other debris. (C)

Corrective Actions: PIC had food employees clean the storage rack and the rolling cart.

Violation #8:

17B: .06(5)(r),(s)Observed three large bags of trash stored on the ground by three rolling trash cans located by the dish machine. At the beginning of the inspection, EHS smelled an odor and followed the odor to the three large bags of trash. Refuse, recyclables, and returnables shall be removed from the premises at a frequency that will minimize the development of objectionable odors and other conditions that attract or harbor insects and rodents. (C)

Corrective Actions: PIC had food employee remove the trash.

Additional remarks:

Cold-Holding was assessed and incompliance unless noted in the temperature log.

No foods were hot holding at the time of inspection.

The GM, Anthony, arrived at the facility near the end of inspection.

The GM went to another store to bring more supplies.

Ensure proper cooling methods are used for foods that are cooled overnight;

1. uncovered in walk-in-cooler

2. uncovered in reach-in-freezers

3. ice bath

Suggested foods are cooled to 41F in utensil pans first before being bagged.

If foods in the prep cooler can not maintain 41F or above, suggested placing foods on time control.

If facility is interested in training, please contact our office in Gwinnett.

A follow-up will be required within 10 Calendar days or by 1/16/26.

A REQUIRED ADDITIONAL ROUTINE INSPECTION WIL BE CONDUCTED WITHIN 60 DAYS OF THE FOLLOW-UP.

Fees will be charged accordingly for any violation which cannot be corrected on-site during inspection.

Repeat violations may result in permit suspension.

Corrections of violations during and after inspection does not change the inspection score.

CLICK HERE to read the full report