Remove ads by Supporting Independent News

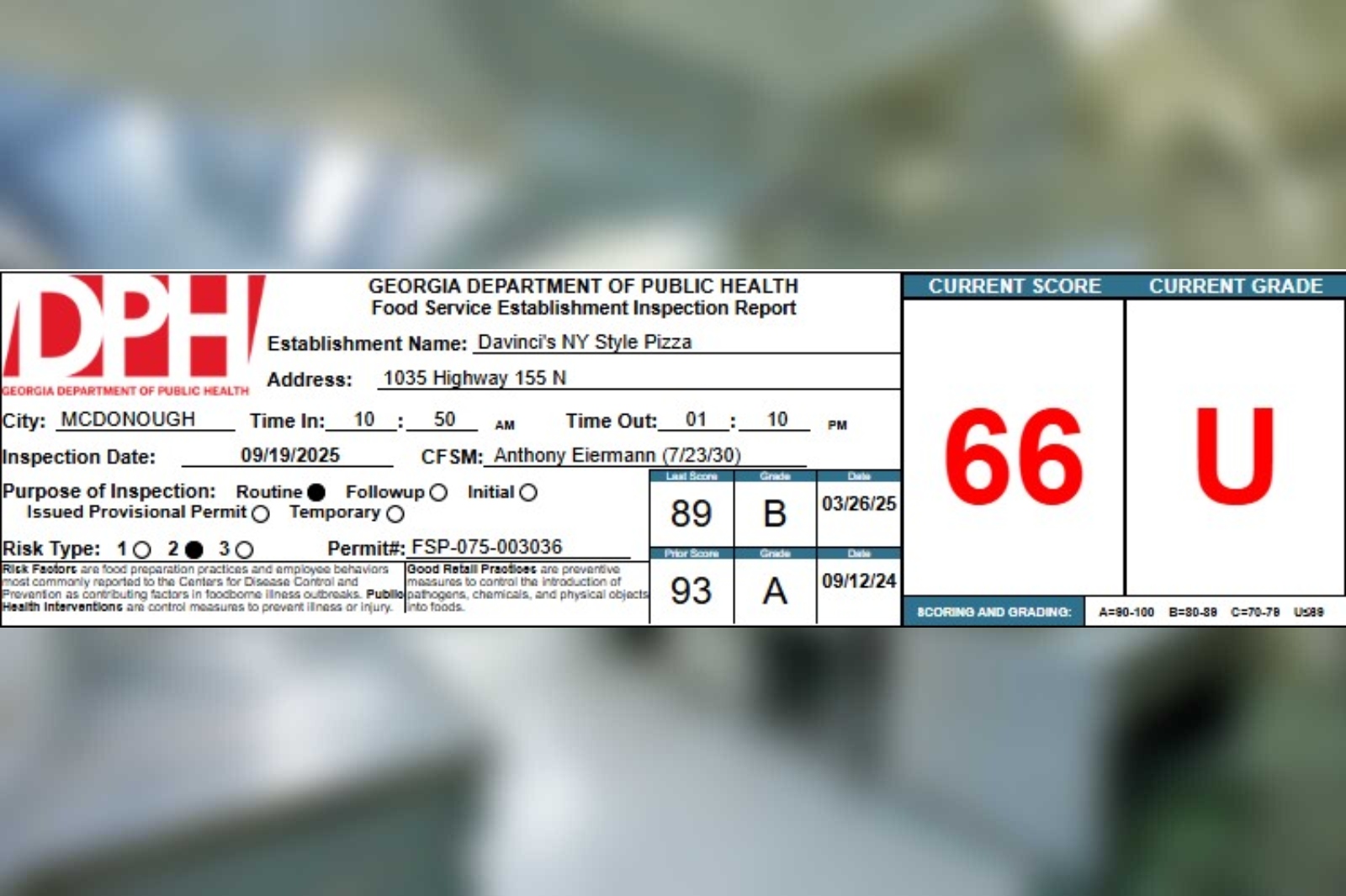

Davinci’s NY Style Pizza, located at 1035 Highway 155 N in McDonough, received a score of 66 points out of a possible 100 points during their 09/19/2025 inspection by the Georgia Department of Public Health.

The violations noted by the inspector were:

Violation #1:

3-1C – food in good condition, safe, and unadulterated

511-6-1.04(1) – safe, unadulterated and honestly presented (p)

Points: 9

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed pizza sauce stored in the walk in cooler with a preparation date of (8/18) with white mold spores. PIC stated that the pizza sauce came from a bad can and was just stored in the walk in cooler. Advised the PIC that bad, moldy, and unadulterated, etc. food items must be discarded and cannot be held in the facility. The pizza sauce was discarded (COS). 511-6-1.04(1) – Safe, unadulterated and Honestly Presented (P) (1) Condition. Food shall be safe, unadulterated, and honestly presented. P

Violation #2:

4-1A – food separated and protected

511-6-1.04(4)(c)1(i)(ii)(iii)(v)(vi)(vii)(viii) – packaged & unpackaged food separation, packaging, and segregation (p, c)

Points: 9

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed an opened container of fries stored in the walk in cooler directly beside boxes of raw chicken wings and a container of prepped raw chicken wings. Advised PIC that food items must be stored according to cooking temperatures to reduce the chances of cross contamination that could lead to a foodborne illness. 511-6-1.04(4)(c)1(i)(ii)(iii)(v)(vi)(vii)(viii) – Packaged & Unpackaged Food Separation, Packaging, and Segregation (P, C) (c) Packaged and Unpackaged Food – Separation, Packaging, and Segregation. 1. Food shall be protected from cross contamination by: (i) Except as specified in paragraph (i)(IV) of this subsection, separating raw animal foods during storage, preparation, holding, and display from: (I) Raw ready-to-eat food including other raw animal food such as fish for sushi or molluscan shellfish, or other raw ready-to-eat food such as fruits and vegetables, P and (II) Cooked ready-to-eat food; and P (III) Fruits and vegetables before they are washed; P (IV) Frozen, commercially processed and packaged raw animal food may be stored or displayed with or above frozen, commercially processed and packaged, ready-to-eat food. (ii) Except when combined as ingredients, separating types of raw animal foods from each other such as beef, fish, lamb, pork, and poultry during storage, preparation, holding, and display by: (I) Using separate equipment for each type, P or (II) Arranging each type of food in equipment so that cross contamination of one type with another is prevented, P and (III) Preparing each type of food at different times or in separate areas; P (iii) Cleaning and sanitizing equipment and utensils; (v) Cleaning hermetically sealed containers of food of visible soil before opening; (vi) Protecting food containers that are received packaged together in a case or overwrap from cuts when the case or overwrap is opened; (vii) Storing damaged, spoiled, or recalled food being held in the food service establishment separate from food, equipment, utensils, linens and single-service and single-use articles; or (viii) Separating fruits and vegetables, before they are washed from ready-to-eat food.

Violation #3:

4-2B – food-contact surfaces: cleaned & sanitized

511-6-1.05(7)(a)1 – equipment, food-contact surfaces,& utensils (pf)

Points: 4

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed a vape pen stored on the cutting board of the salad prep top cooler. PIC removed the vape pen, but placed it on another prep surface right by the meat slicer and a pack of cigarettes. Cigarettes and vape pens should be stored in a designated area where items will not cause contamination to food contact surfaces. Observed hair on the ice inside of the clean glasses cooler at the bar. The cooler must be cleaned to sight and touch. Observed the bulk ice machine with black and pink mold accumulation. The ice machine must be drained and properly cleaned. 511-6-1.05(7)(a)1 – Equipment, Food-Contact Surfaces,& Utensils (Pf) (7) Cleaning of Equipment and Utensils. (a) Equipment, Food-Contact Surfaces, and Utensils. 1. Equipment food-contact surfaces and utensils shall be clean to sight and touch. Pf.

Violation #4:

6-2 – proper date marking and disposition

511-6-1.04(6)(h) – ready-to-eat time/temperature control for safety food, disposition (p)

Points: 4

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed several food items stored in the reach in cooler with an expiration date (meatballs prepped on 9/4, ziti noodle prepped on 9/8, angel hair noodles prepped on 9/9, pizza sauce prepped on 8/18). All items were discarded (COS).

Violation #5:

12A – contamination prevented during food preparation, storage, display

511-6-1.04(4)(q) – food storage (c)

Points: 3

Corrected during inspection?: No

Repeat: Yes

Inspector Notes: Observed fries in the walk in cooler not covered. Advised PIC to cover foods to prevent potential contamination. Observed two containers of oil and seasonings (dry storage) stored on the floor. All food items must be stored 6 inches or higher off the floor. 511-6-1.04(4)(q) – Food Storage (C) (q) Food Storage. 1. Except as specified in paragraphs 2 and 3 of this subsection, food shall be protected from contamination by storing the food: (i) In a clean, dry location; (ii) Where it is not exposed to splash, dust, or other contamination; and (iii) At least 6 inches (15 cm) above the floor. 2. Food in packages and working containers may be stored less than 6 inches (15 cm) above the floor on case lot handling equipment if the equipment can be moved by hand or by conveniently available apparatuses such as hand trucks and forklifts. 3. Pressurized beverage containers, cased food in waterproof containers such as bottles or cans, and milk containers in plastic crates may be stored on a floor that is clean and not exposed to floor moisture.

Violation #6:

12B – personal cleanliness

511-6-1.03(5)(i) – hair restraints (c)

Points: 3

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed an employee come into the kitchen and make a salad without a hair restraint. All employees handling or preparing food items must have hair properly restrained. Counter staff, hostesses, wait staff, etc. that presents a risk of contaminating exposed food, clean utensils and linens, and unwrapped single-service and single-use articles must restrain hair. 511-6-1.03(5)(i) – Hair Restraints (C) (i) Hair Restraints. 1. Employees preparing or handling food shall use effective and clean, disposable or easily cleanable nets or other hair restraints approved by the Health Authority, worn properly to restrain loose hair including beards and mustaches longer than one half inch.

Violation #7:

13A – posted: permit/inspection/choking poster/handwashing

511-6-1.07(3)(d) – handwashing signage (c)

Points: 1

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed no handwashing sign on the front handwashing sink. 511-6-1.07(3)(d) – Handwashing Signage (C) (d) Handwashing Signage. A sign or poster that notifies food employees to wash their hands shall be provided at all handwashing sinks used by food employees and shall be clearly visible to food employees.

Violation #8:

15A – food and nonfood-contact surfaces cleanable, properly designed, constructed, and used

511-6-1.05(2)(c) – multiuse food-contact surfaces (pf)

Points: 1

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed multiuse containers with food products in them (raw chicken, Caesar dressing, bacon bites) in bad repair. 511-6-1.05(2)(c) – Multiuse Food-Contact Surfaces (Pf) (c) Multiuse Food-Contact Surfaces. 1. Multiuse food-contact surfaces shall be: (i) Smooth; Pf (ii) Free of breaks, open seams, cracks, chips, inclusions, pits, and similar imperfections; Pf (iii) Free of sharp internal angles, corners, and crevices; Pf (iv) Finished to have smooth welds and joints; Pf and (v) Except as specified in paragraph 2 of this subsection, accessible for cleaning and inspection by one of the following methods: (I) Without being disassembled, Pf (II) By disassembling without the use of tools, Pf or (III) By easy disassembling with the use of handheld tools commonly available to maintenance and cleaning personnel such as screwdrivers, pliers, open-end wrenches, and Allen wrenches. Pf 2. The requirement in paragraph 1(v) of this subsection does not apply to cooking oil storage tanks, Distribution lines for cooking oils, or beverage syrup lines or tubes.

Violation #9:

15C – nonfood-contact surfaces clean

511-6-1.05(7)(a)2,3 – equipment, food/nonfood-contact surfaces, and utensils, food-contact surfaces of cooking equipment & nonfood-contact surfaces free of accumulations (c)

Points: 1

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed an excessive amount of black debris/build up on the vents/blowers and the ceilings in the walk in cooler. 511-6-1.05(7)(a)2,3 – Equipment, Food/Nonfood-Contact Surfaces, and Utensils, food-contact surfaces of cooking equipment & nonfood-contact surfaces free of accumulations (C) 2. The food-contact surfaces of cooking equipment and pans shall be kept free of encrusted grease deposits and other soil accumulations. 3. Nonfood-contact surfaces of equipment shall be kept free of an accumulation of dust, dirt, food residue, and other debris.

Violation #10:

17C – physical facilities installed, maintained, and clean

511-6-1.07(5)(a),(b) – good repair, physical facilities maintained; cleaning, frequency & restrictions, cleaned often enough to keep them clean (c)

Points: 1

Corrected during inspection?: No

Repeat: Yes

Inspector Notes: Observed floor tile in bad repair in the three compartment sink area, by the back door, and in front of the salad prep cooler. This is a 2nd consecutive repeat, the floors must be repaired to avoid mold growth underneath the floor tile. Observed the floors in need of cleaning behind the ice machine and underneath the 3-compartment sink and dishwasher. Observed holes on the walls behind the 3-compartment sink and in the dry storage room that must be completely sealed to prevent bugs from entering into the kitchen. Observed the ceiling tile throughout the kitchen with build up and dust debris. Observed the paint chipping on the walls and ceilings in the walk in cooler. The walls and ceilings must be properly sealed to avoid contamination of food items stored in the walk in cooler. 511-6-1.07(5)(a),(b) – Good Repair, physical facilities maintained; Cleaning, Frequency & Restrictions, cleaned often enough to keep them clean (C) (5) Maintenance and Operation. (a) Good Repair. All physical facilities shall be maintained in good repair. (b) Cleaning, Frequency and Restrictions. 1. The physical facilities shall be cleaned as often as necessary to keep them clean and by methods that prevent contamination of food products. 2. Except for cleaning that is necessary due to a spill or other accident, cleaning shall be done during periods when the least amount of food is exposed, such as after closing.

Violation #11:

17D – adequate ventilation and lighting; designated areas used

511-6-1.07(2)(i) – light bulbs, protective shielding (c)

Points: 1

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed a cracked light shield in the walk in cooler. The light shield must be removed and replaced. Observed light shields missing over the lights in the dry storage area and the utility room.

Violation #12:

17D – adequate ventilation and lighting; designated areas used

511-6-1.07(3)(g) – mechanical ventilation, sufficient capacity to prevent buildup of heat, steam, smoke, fumes & odors (c)

Points: 1

Corrected during inspection?: No

Repeat: Yes

Inspector Notes: Observed rust build up on the vent in the dry storage and ceiling grids throughout the kitchen area. The rust must be treated, cleaned, and properly sealed to prevent contamination of food items.

Additional remarks:

A reinspection will be conducted on Monday, September 29, 2025. A fee of $100.00 must be submitted to the Henry County Health Department for a reinspection by 9/23/25. A plan of action outlining all violations and how they will be corrected must be submitted to Sabrina Young via email at sabrina.young@dph.ga.gov by 9/23/2025.

CLICK HERE to read the full report