Remove ads by Supporting Independent News

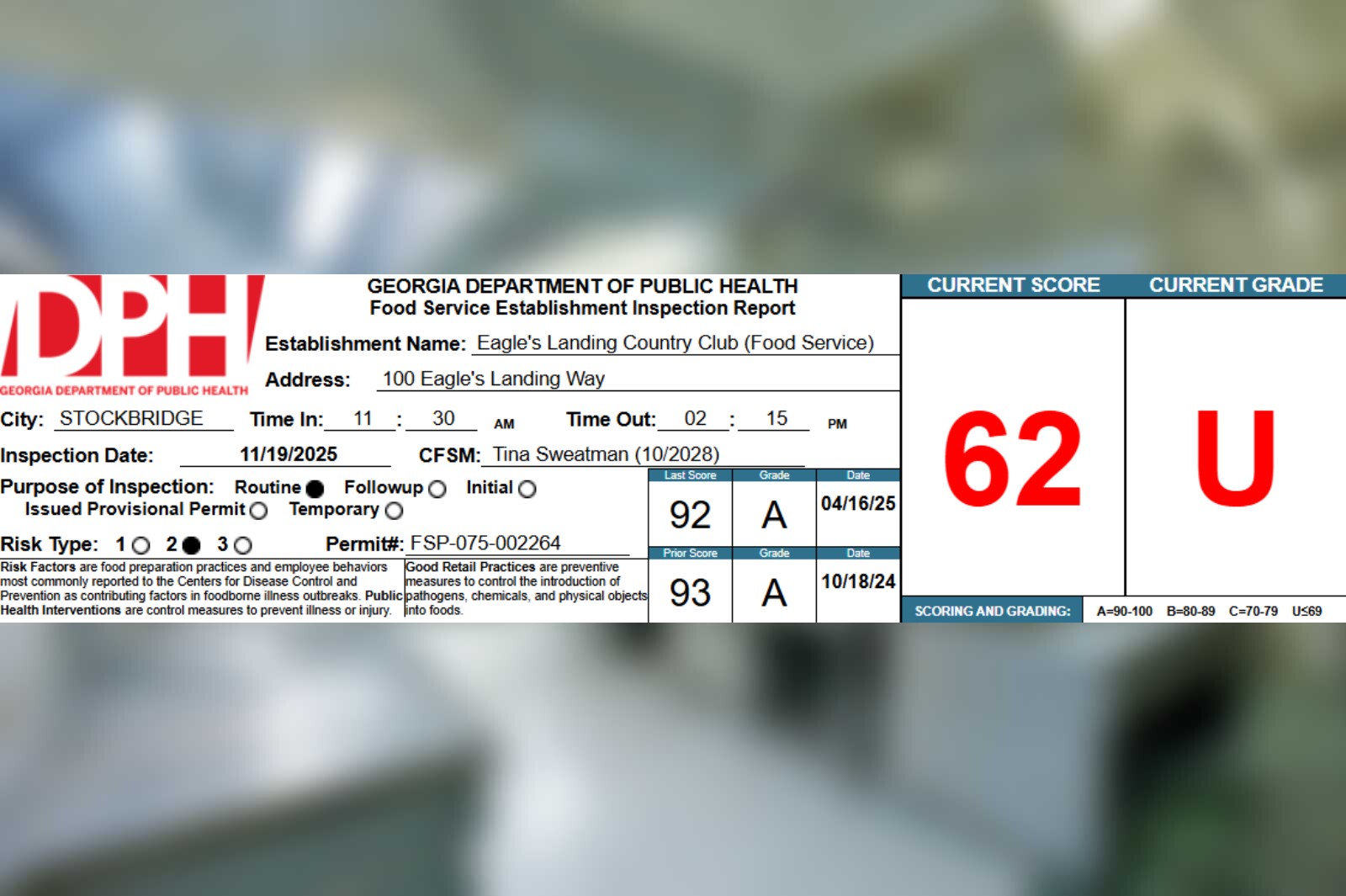

Eagle’s Landing Country Club (Food Service), located at 100 Eagle’s Landing Way in Stockbridge, received a score of 62 points out of a possible 100 points during their 11/19/2025 inspection by the Georgia Department of Public Health.

The violations noted by the inspector were:

Violation #1:

2-2D – adequate handwashing facilities supplied & accessible

511-6-1.07(3)(a) – handwashing cleanser, availability (pf)

Points: 4

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed no hand washing cleanser at the front hand sink in the main kitchen. Hand soap was provided to the hand sink during inspection. Observed food debris in the hand sink near the back of the kitchen.

Violation #2:

4-1A – food separated and protected

511-6-1.04(4)(c)1(i)(ii)(iii)(v)(vi)(vii)(viii) – packaged & unpackaged food separation, packaging, and segregation (p, c)

Points: 9

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed raw and cooked food improperly stored vertical in the following order: raw pork, cooked chicken with raw sausage links, raw shrimp and raw salmon, hot dogs, and raw bison, crab cakes. 511-6-1.04(4)(c)1(i)(ii)(iii)(v)(vi)(vii)(viii) – Packaged & Unpackaged Food Separation, Packaging, and Segregation (P, C) (c) Packaged and Unpackaged Food – Separation, Packaging, and Segregation. 1. Food shall be protected from cross contamination by: (i) Except as specified in paragraph (i)(IV) of this subsection, separating raw animal foods during storage, preparation, holding, and display from: (I) Raw ready-to-eat food including other raw animal food such as fish for sushi or molluscan shellfish, or other raw ready-to-eat food such as fruits and vegetables, P and (II) Cooked ready-to-eat food; and P (III) Fruits and vegetables before they are washed; P (IV) Frozen, commercially processed and packaged raw animal food may be stored or displayed with or above frozen, commercially processed and packaged, ready-to-eat food. (ii) Except when combined as ingredients, separating types of raw animal foods from each other such as beef, fish, lamb, pork, and poultry during storage, preparation, holding, and display by: (I) Using separate equipment for each type, P or (II) Arranging each type of food in equipment so that cross contamination of one type with another is prevented, P and (III) Preparing each type of food at different times or in separate areas; P (iii) Cleaning and sanitizing equipment and utensils; (v) Cleaning hermetically sealed containers of food of visible soil before opening; (vi) Protecting food containers that are received packaged together in a case or overwrap from cuts when the case or overwrap is opened; (vii) Storing damaged, spoiled, or recalled food being held in the food service establishment separate from food, equipment, utensils, linens and single-service and single-use articles; or (viii) Separating fruits and vegetables, before they are washed from ready-to-eat food.

Violation #3:

4-2A – food stored covered

511-6-1.04(4)(c)1(iv) – packaged & unpackaged food, food stored covered(c)

Points: 4

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed four containers of sliced cheese stored uncovered in a reach in cooler with leaking condensation.

Violation #4:

4-2B – food-contact surfaces: cleaned & sanitized

511-6-1.05(7)(a)1 – equipment, food-contact surfaces,& utensils (pf)

Points: 4

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed clean utensils stored in containers with food debris in the storage room located in the front of the kitchen. Observed build up on the soda nozzles in the back of the kitchen.

Violation #5:

6-1A – proper cold holding temperatures

511-6-1.04(6)(f) – time/temperature control for safety; cold holding (p)

Points: 9

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed multiple TCS food items cold held above 41F in the reach in and walk in coolers. Please ensure that all cold TCS items are held at 41F or below. Manager discarded all items that were not properly held at 41F. 511-6-1.04(6)(f) – Time/Temperature Control for Safety; Cold Holding (P) (f) Time/Temperature Control for Safety Food, Hot and Cold Holding. Except during preparation, cooking, or cooling, or when time is used as the public health control, time/temperature control for safety food shall be maintained at 41°F (5°C) or below or 135°F (57°C) or above, except that roasts cooked to a temperature and for a time specified in subsection (5)(a)2 of this Rule and reheated using the same temperature and time conditions as cooking may be held at a temperature of 130°F (54°C) or above. P

Violation #6:

6-2 – proper date marking and disposition

511-6-1.04(6)(g) – ready-to-eat time/temperature control for safety food, date marking (pf)

Points: 4

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed employees back-dating food items that were prepared prior to today and held in the establishment over 24 hours. Observed turkey deli meat and feta cheese crumbles in the front reach in cooler and the raw salmon and crab cakes in the walk in cooler did not contain any date marking information. 511-6-1.04(6)(g) – Ready-To-Eat Time/Temperature Control for Safety Food, Date Marking (Pf) (g) Ready-to-Eat Time/Temperature Control for Safety Food, Date Marking 1. Except when packaging food using a reduced oxygen packaging method, and except as specified in paragraphs 5 and 6 of this subsection, refrigerated, ready-to-eat, time/temperature control for safety food prepared and held in a food establishment for more than 24 hours shall be clearly marked to indicate the date or day by which the food shall be consumed on the premises, sold, or discarded, when held at a temperature of 41°F (5°C) or below for a maximum of 7 days. The day of preparation shall be counted as Day 1. Pf 2. Except as specified in paragraphs 5 through 7 of this subsection, refrigerated, ready-to-eat, time/temperature control for safety food prepared and packaged by a food processing plant shall be clearly marked, at the time the original container is opened in a food service establishment and if the food is held for more than 24 hours, to indicate the date or day by which the food shall be consumed on the premises, sold, or discarded, when held at a temperature of 41°F (5°C) or below for a maximum of 7 days after the original container is opened. The day the original container is opened in the food service establishment shall be counted as Day 1, except, the day or date marked by the food service establishment may not exceed a manufacturer’s use by date if the manufacturer determined the use-by date based on food safety; Pf 3. A refrigerated, ready-to-eat, time/temperature control for safety food ingredient or a portion of a refrigerated, ready-to-eat, time/temperature control for safety food that is subsequently combined with additional ingredients or portions of food shall retain the date marking of the earliest-prepared or first-prepared ingredient. Pf 4. A date marking system that meets the criteria stated in paragraphs 1 and 2 of this subsection may include: (i) Using a method approved by the Health Authority for refrigerated, ready-to-eat time / temperature control for safety food that is frequently rewrapped, such as lunchmeat or a roast, or for which date marking is impractical, such as soft serve mix or milk in a dispensing machine; (ii) Marking the date or day of preparation, with a procedure to discard the food on or before the last date or day by which the food must be consumed on the premises, sold, or discarded; (iii) Marking the date or day the original container is opened in a food service establishment, with a procedure to discard the food on or before the last date or day by which the food must be consumed on the premises, sold, or discarded; or (iv) Using calendar dates, days of the week, color-coded marks, or other effective marking methods, provided that the marking system is disclosed to the Health Authority upon request. 5. The requirements in paragraphs 1 and 2 of this subsection do not apply to individual meal portions served or repackaged for sale from a bulk container upon a consumer’s request. 6. The requirements in paragraphs 1 and 2 of this subsection do not apply to shellstock. 7. The requirement in paragraph 2 of this subsection does not apply to the following foods prepared and packaged by a food processing plant inspected by a Health Authority: (i) Deli salads, such as ham salad, seafood salad, chicken salad, egg salad, pasta salad, potato salad, and macaroni salad, manufactured in accordance with 21 CFR 117 Current good manufacturing practice in manufacturing, packing, or holding human food; (ii) Hard cheeses containing not more than 39% moisture as defined in 21 CFR 133 Cheeses and related cheese products, such as cheddar, gruyere, parmesan and reggiano, and romano; (iii) Semi-soft cheeses containing more than 39% moisture, but not more than 50% moisture, as defined in 21 CFR 133 Cheeses and related cheese products, such as blue, edam, gorgonzola, gouda, and monterey jack; (iv) Cultured dairy products as defined in 21 CFR 131 Milk and cream, such as yogurt, sour cream, and buttermilk; (v) Preserved fish products, such as pickled herring and dried or salted cod, and other acidified fish products defined in 21 CFR 114 Acidified foods; (vi) Shelf stable, dry fermented sausages, such as pepperoni and Genoa salami; and (vii) Shelf stable salt-cured products, such as prosciutto and Parma ham.

Violation #7:

6-2 – proper date marking and disposition

511-6-1.04(6)(h) – ready-to-eat time/temperature control for safety food, disposition (p)

Points: 4

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed an opened bag of blue cheese date marked from 10/22/25-10/27/25 in the front reach in cooler. An employee discarded the blue cheese. 511-6-1.04(6)(h) – Ready-To-Eat Time/Temperature Control for Safety Food, Disposition (P) (h) Ready-to-Eat, Time/Temperature Control for Safety Food, Disposition. 1. A food that requires datemarking shall be discarded if it: (i) Exceeds 7 days, not including the time that the product is frozen; P (ii) Is in a container or package that does not bear a date or day; P or (iii) Is inappropriately marked with a date or day that exceeds 7 days . P 2. Refrigerated, ready-to-eat, time / temperature control for safety food prepared in a food service establishment and dispensed through a vending machine with an automatic shutoff control shall be discarded if it exceeds 7 days.

Violation #8:

8-2B – toxic substances properly identified, stored, used

511-6-1.07(6)(g) – chemical sanitizers, criteria (p)

Points: 4

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed 3 compartment sink quat sanitizer solution 500ppm. Manager was advised to dilute the sanitizer with warm water until the dispenser if recalibrated to dispense the appropriate concentration is between 200ppm-400ppm.

Violation #9:

8-2B – toxic substances properly identified, stored, used

511-6-1.07(6)(b) – working containers, common name (pf)

Points: 4

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed working chemical bottle with an unidentifiable blue liquid located by the 3 compartment sink.

Violation #10:

14A – in-use utensils: properly stored

511-6-1.04(4)(k) – in-use utensils, between-use storage (c)

Points: 1

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed ice scoop, soda nozzles, and silverware stored in stagnant water of 60F. Manager was advised to remove items from the stagnant water and properly re-wash, rinse, and sanitize the utensils. If ice scoops are to be stored in water, the water must be 135F or above. Silverware and soda nozzles must be air dried. Observed utensils stored directed next to the back hand sink in the kitchen.

Violation #11:

15A – food and nonfood-contact surfaces cleanable, properly designed, constructed, and used

511-6-1.05(2)(a) – equipment and utensils, constructed of durable materials (c)

Points: 1

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed back hand sink in need of splash guards on both sides of the sink. Observed reach in cooler at the end of the prep/cook line with condensation leaking inside of the cooler causing water to pool at the bottom of the cooler. This cooler has also been previously observed not being able to keep items 41F or below during past inspections. Due to the history of problems of the reach in cooler at the end of the prep line, it is recommended by the health authorities that this reach in cooler is replaced immediately. Observed reach in cooler in the bar with water pooling at the bottom due to condensation leak and mold build up around the piping.

Violation #12:

15C – nonfood-contact surfaces clean

511-6-1.05(7)(d) – nonfood-contact surfaces (c)

Points: 1

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed cabinets under the prep line with debris. Please clean all debris. Observed shelves throughout the kitchen, walk in cooler, and reach in coolers with rust. Please have shelves repainted and sealed. Observed walk in cooler plastic curtain with dust build up. Observed back of food prep line equipment with dust build up. Observed ash and food debris in between the lowboy cooler and grill. Observed food build up in the microwave. Observed build up at the bottom of the reach in freezer.

Violation #13:

17B – garbage/refuse properly disposed; facilities maintained

511-6-1.06(5)(n) – covering receptacles (c)

Points: 1

Corrected during inspection?: No

Repeat: Yes

Inspector Notes: Observed dumpster without a cover, leaving dumpster opened for pest entry. Please have dumpster replaced with one that had lid covers to prevent pests from entering the dumpster.

Violation #14:

17C – physical facilities installed, maintained, and clean

511-6-1.07(5)(a),(b) – good repair, physical facilities maintained; cleaning, frequency & restrictions, cleaned often enough to keep them clean (c)

Points: 1

Corrected during inspection?: No

Repeat: Yes

Inspector Notes: Observed dust build up on ceiling tiles, light shields, and walls of the kitchen. Observed dust accumulation on the walls and ceilings of the walk in cooler due to dusty cooler fan. Observed floors in disrepair in the kitchen. Observed baseboards in disrepair in the downstairs food storage areas.

Violation #15:

17D – adequate ventilation and lighting; designated areas used

511-6-1.07(5)(d) – cleaning ventilation system, nuisance & discharge prohibition, cleaned in way not to cause contamination or create a public health hazard (c)

Points: 1

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed fowl sewage odor coming from the mop sink area.

Additional remarks:

Conducted inspection with EHS III, Robert Lewis. Follow up inspection will be conducted December 1st.

Due to the history of problems of the reach in cooler at the end of the prep line, it is highly recommended by the health authorities that this reach in cooler is replaced immediately.

CLICK HERE to read the full report