Remove ads by Supporting Independent News

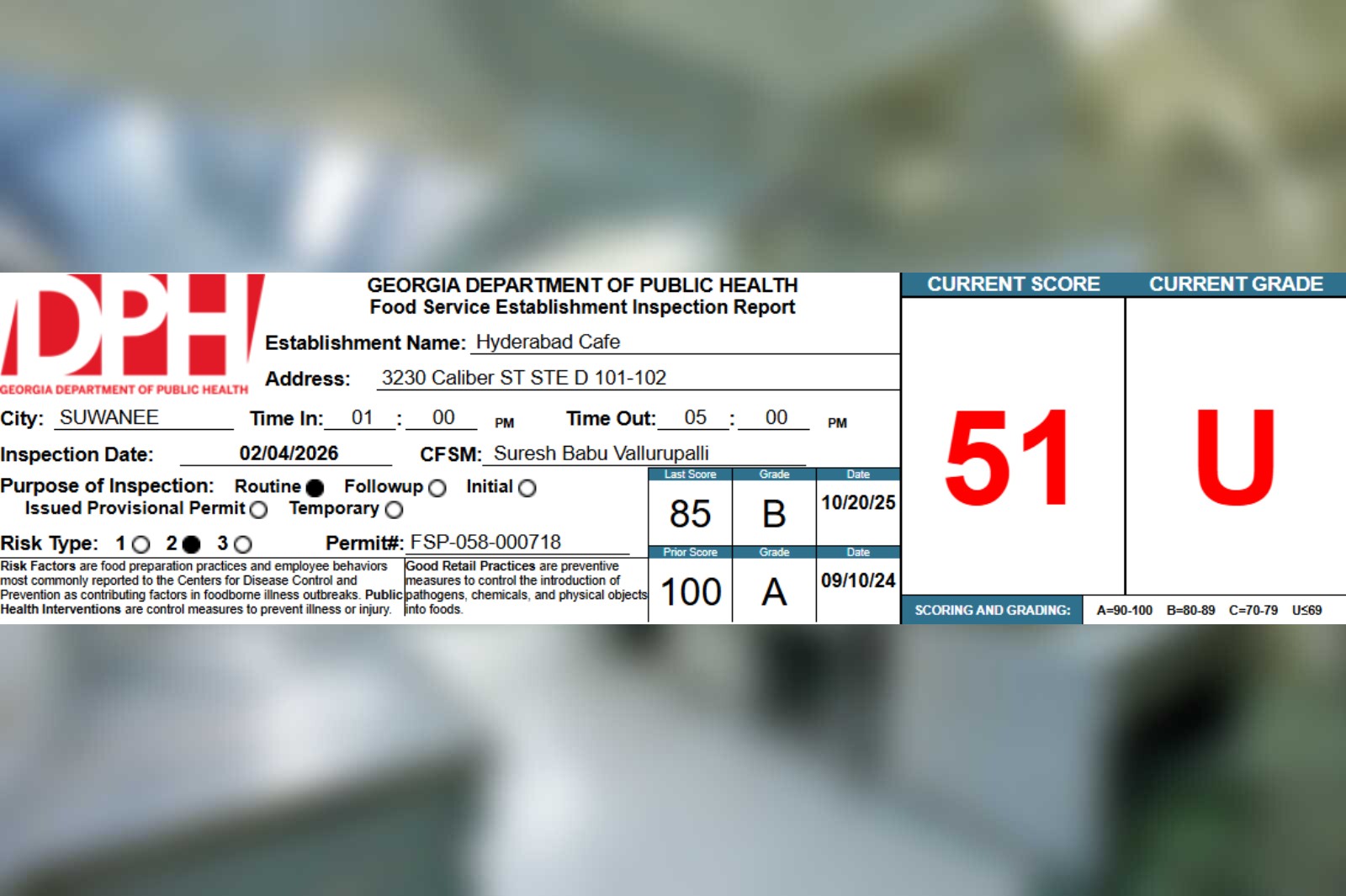

Hyderabad Cafe, located at 3230 Caliber St Ste D 101-102 in Suwanee, received a score of 51 points out of a possible 100 points during their 02/04/2026 inspection by the Georgia Department of Public Health.

The violations noted by the inspector were:

Violation #1:

1-2A – pic present, demonstrates knowledge, performs duties

511-6-1.03(2)(a)-(n)(p),(q) – responsibility of pic (pf)

Points: 4

Corrected during inspection?: No

Repeat: No

Inspector Notes: Person in charge not performing duties; employee hand washing was not being monitored. Person in charge not performing duties; not ensuring employees are cooking Time/Temperature Control for Safety Foods, through daily oversight of the employees’routine monitoring of the cooking temperatures.

Violation #2:

2-1C – no bare hand contact with ready-to-eat foods or approved alternate method properly followed

511-6-1.04(4)(a)1,2,3,4(i) – preventing contamination from hands (p), (pf), (c)

Points: 9

Corrected during inspection?: No

Repeat: No

Inspector Notes: observed RTE foods handled without gloves. Inspector intervention- food discarded. corrective action- food employees shall not contact exposed, ready-to-eat food with their bare hands and shall use suitable utensils such as deli tissue, spatulas, tongs, single-use gloves, or dispensing equipment. P

Violation #3:

2-2A – management knowledge, responsibilities, reporting

511-6-1.03(2)(o) – person-in-charge duties (pf)

Points: 4

Corrected during inspection?: No

Repeat: No

Inspector Notes: The PIC could not provide documentation or otherwise satisfactorily demonstrate during the inspection, that all food employees and conditional employees are informed of their responsibility to report to management information about their health and activities as it relates to diseases that are transmissible through food. Corrective action: Provide a file with employee health agreements available for review during inspections. A blank copy of the employee health agreement was provided at time of inspection.

Violation #4:

2-2B – proper eating, tasting, drinking, or tobacco use

511-6-1.03(5)(k)1&2 – eating, drinking, or using tobacco (c)

Points: 4

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed an open beverage container on a food preparation table or over/next to clean equipment/utensils. Corrective action: Employees shall consume food only in approved designated areas separate from food preparation and serving areas, equipment or utensil areas and food storage areas. However, drinking from a single service beverage cup with a secure lid and straw that is handled to prevent contamination of the employee’s hands, the container, exposed food, clean equipment, utensils and linens, unwrapped single-service and single-use articles will be allowed.

Violation #5:

2-2D – adequate handwashing facilities supplied & accessible

511-6-1.06(2)(g) – handwashing sinks, nos/capacities (pf)

Points: 4

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Hand sink to the left of the cookline was blocked with a rolling cart. COS- cart was moved. Corrective action- Keep hand sink accessible at all times.

Violation #6:

2-2D – adequate handwashing facilities supplied & accessible

511-6-1.07(3)(b) – hand drying provision (pf)

Points: 4

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: EHS observed the front food service hand sink, the left cookline hand sink, and the wash area hand sink did not have paper towels. COS- napkins were temporarily placed at the hand wash stations until replacement rolls are obtained. Corrective action- provide paper towels at hand sink at all times, order and keep on hand an adequate amount of paper towels.

Violation #7:

2-2D – adequate handwashing facilities supplied & accessible

Points: 4

Corrected during inspection?: No

Repeat: No

Inspector Notes: EHS observe the hand sink at the right side of the cookline has been removed. Corrective action- replace hand sink and supply with mounted soap and paper towels, and a waste bine.

Violation #8:

2-2D – adequate handwashing facilities supplied & accessible

511-6-1.06(2)(g) – handwashing sinks, nos/capacities (pf)

Points: 4

Corrected during inspection?: No

Repeat: No

Inspector Notes: EHS observed the previously designated dry storage room has been converted to a dessert prep area. Apply for a plan revision with Forsyth County environmental health dept for review of change. The area now requires at minimum a hand sink.

Violation #9:

2-2E – response procedures for vomiting & diarrheal events

511-6-1.03(6) – clean-up of vomiting and diarrheal events(pf)

Points: 4

Corrected during inspection?: No

Repeat: No

Inspector Notes: Establishment does not have established procedures for employees to follow when responding to vomiting or diarrheal events that involve the discharge of vomitus or fecal matter onto surfaces in the food establishment. Corrective action: Provide written procedures and designate an area to post the procedures, a spill kit, and the cleaning agent effective for use against norovirus. Facility has bleach as an effective cleaning agent.

Violation #10:

4-1A – food separated and protected

511-6-1.04(4)(c)1(i)(ii)(iii)(v)(vi)(vii)(viii) – packaged & unpackaged food separation, packaging, and segregation (p, c)

Points: 9

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed raw animal food stored over ready-to-eat food in the walk-in cooler. Chicken was stored on the top shelf above RTE foods. COS- The chicken was placed on a separate shelving rack during the inspection. Corrective action: reorganize the walk-in cooler to ensure easy separation and proper vertical storage of RTE and animal proteins. Food storage order educational handout was provided at time of inspection.

Violation #11:

6-1A – proper cold holding temperatures

511-6-1.04(6)(f) – time/temperature control for safety; cold holding (p)

Points: 9

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed potentially hazardous food cold held at greater than 41 degrees Fahrenheit. See temperature log. COS- foods discarded. Corrective action maintain potentially hazardous food cold held at or below 41F. Revise cooking procedures to ensure the cream and eggs are cold held until ready for use on the cookline.

Violation #12:

10D – food properly labeled; original container

511-6-1.04(4)(d) – food storage containers identified with common name of food (c)

Points: 3

Corrected during inspection?: No

Repeat: No

Inspector Notes: Working containers of food removed from original container not identified by common name. Corrective action- label the bulk food containers across from the front food service cookline

Violation #13:

12A – contamination prevented during food preparation, storage, display

511-6-1.04(4)(q) – food storage (c)

Points: 3

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed foods stored on the floor of the walk-in freezer. Corrective action: obtain additional shelving units or racks to store food 6″ off the floor.

Violation #14:

12B – personal cleanliness

511-6-1.03(5)(j) – hair restraints (c)

Points: 3

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed employee with no beard guard/restraint. Corrective action: provide beard nets for food handlers with facial hair longer than 1/2 inch.

Violation #15:

14A – in-use utensils: properly stored

511-6-1.04(4)(k) – in-use utensils, between-use storage (c)

Points: 1

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed in use ladles stored in water at the stove. Observed spoons stored in water at the idly warmer. COS- water discarded and utensils washed and sanitized. Corrective action: store in-use utensils in a clean dry pan, or place in water that is hot held at or above 135F.

Violation #16:

14A – in-use utensils: properly stored

511-6-1.04(4)(k) – in-use utensils, between-use storage (c)

Points: 1

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed ice scoop with handle in contact with ice. COS-removed from ice and place the scoop holder. Corrective action: ensure the ice scoop is properly placed in the scoop holder between uses.

Violation #17:

14B – utensils, equipment and linens: properly stored, dried, handled

Points: 1

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed large pots and lids stored on the floor in the dish pit area. Corrective action: provide a rack or other storage system to store pots off the floor.

Violation #18:

15A – food and nonfood-contact surfaces cleanable, properly designed, constructed, and used

511-6-1.05(1)(a) – materials, general requirements (p, c)

Points: 1

Corrected during inspection?: No

Repeat: No

Inspector Notes: 5 gallons blue, white, green, and orange buckets used to store bulk food (Location: Throughout the facility, walk-in cooler, walk-in freezer). Corrective action: Obtain reusable food grade containers to store food.

Violation #19:

15A – food and nonfood-contact surfaces cleanable, properly designed, constructed, and used

Points: 1

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed shelving units and equipment that had shipping plastic wrap. Corrective action: remove the wrap and clean and sanitize the non-food contact surfaces.

Violation #20:

15A – food and nonfood-contact surfaces cleanable, properly designed, constructed, and used

Points: 1

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed bottom shelves that are not 6″ off the floor. Corrective action: adjust shelves so that the bottom shelves are 6″ off the floor to provide adequate cleaning space.

Violation #21:

15B – warewashing facilities: installed, maintained, used; test strips

511-6-1.05(3)(h),(i),(j) – temperature measuring device, manual warewashing; sanitizing solutions, testing device (pf)

Points: 1

Corrected during inspection?: No

Repeat: No

Inspector Notes: Facility does not have chemical test strips for use at the 3-compartment sink, dish machine, or sani-buckets. Corrective action: obtain test strips.

Violation #22:

16A – hot and cold water available; adequate pressure

511-6-1.06(1)(g),(h) – water supply, capacity; pressure (pf)

Points: 2

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed the meat sink was missing the faucet. Corrective action: replace broken faucet.

Violation #23:

16A – hot and cold water available; adequate pressure

511-6-1.06(1)(g),(h) – water supply, capacity; pressure (pf)

Points: 2

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed the cold-water pressure at the 3-compartment sink was low. Corrective action: adjust the pressure (flow of the cold water at the 3-compartment sink) to quickly fill the sanitization sink.

Violation #24:

17D – adequate ventilation and lighting; designated areas used

511-6-1.07(3)(f) – lighting intensity, adequate in food prep, storage & service areas (c)

Points: 1

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed insufficient lighting in the walk in cooler. Corrective action: At least 10 foot candles (108 lux) at a distance of 30 inches (75 cm) above the floor, in walk-in refrigeration units and dry food storage areas and in other areas and rooms during periods of cleaning;

Violation #25:

17D – adequate ventilation and lighting; designated areas used

511-6-1.05(2)(n) – exhaust ventilation hood systems, designed to prevent grease or condensation from dripping on food/equipment (c)

Points: 1

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed gaps in the vent hood filters and drip pan missing in hood #1. Corrective action: Replace vent hood filter to ensure there are no gaps and install a drip pan. Have vent hoods serviced regularly.

Violation #26:

17D – adequate ventilation and lighting; designated areas used

511-6-1.07(4)(b) – designated areas for employee activity, located to prevent contamination of food, equipment, utensils, linens, & single service articles (c)

Points: 1

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed employee belongs in various shelves throughout the kitchen. Corrective action: provide designated space for employee belonging storage.

Violation #27:

18 – insects, rodents, and animals not present

511-6-1.07(2)(m) – outer openings protected (c)

Points: 3

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed a one-inch gap between the back door and its threshold. Corrective action: Replace threshold and/or add a floor sweep to the door to seal the gap and protect the outer opening of the establishment.

Additional remarks:

This facility has germicidal bleach as a cleaning agent effective for use against norovirus.

LTDM reading 50ppm Cl

3-compartment sink sanitization solution reading 300ppm QAC

CLICK HERE to read the full report