Get notified by email when this case is updated.

Remove ads by Supporting Independent News

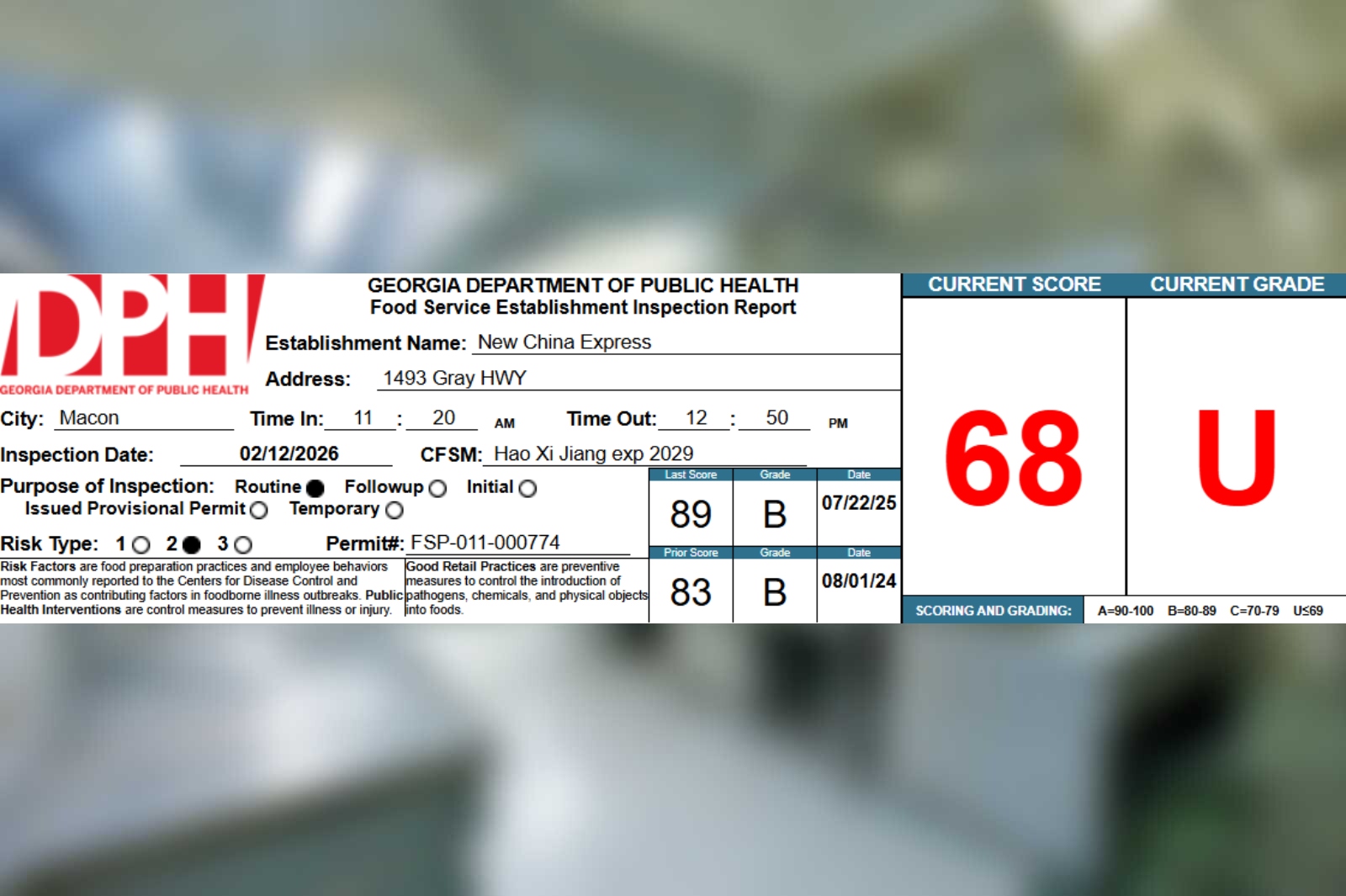

New China Express, located at 1493 Gray Hwy in Macon, received a score of 68 points out of a possible 100 points during their 02/12/2026 inspection by the Georgia Department of Public Health.

The violations noted by the inspector were:

Violation #1:

2-1B – hands clean and properly washed

511-6-1.03(5)(c) – when to wash (p)

Points: 9

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed PIC move from register to fryers (handling fryers baskets), and plating meals without handwashing before handling equipment multiple times. (c) When to Wash. 1. Food employees shall clean their hands and exposed portions of their arms immediately before engaging in food preparation including working with exposed food, clean equipment and utensils, and unwrapped single-service and single-use articles P and: (i) After touching bare human body parts other than clean hands and clean, exposed arms; P (ii) After using the toilet room; P (iii) After caring for or handling service animals or aquatic animals; P (iv) After coughing, sneezing, using a handkerchief or disposable tissue, using tobacco products or electronic devices that simulate tobacco smoking, eating or drinking, except for drinking from a closed beverage container and the container is handled to prevent contamination of the hands;P (v) After handling soiled equipment or utensils; P (vi) During food preparation, as often as necessary to remove soil and contamination and to prevent cross contamination when changing tasks; P (vii) When switching between working with raw food and working with ready-to-eat food; P (viii) Before donning gloves to initiate a task that involves working with food; P and (ix) After engaging in other activities that contaminate the hands. P 2. All employees shall wash hands before leaving the restroom. All food employees leaving the restroom shall wash their hands again upon re-entering the food preparation area. EHS informed him of the need to wash hands. He stated he was aware but that he wasn’t cooking.

Violation #2:

2-2D – adequate handwashing facilities supplied & accessible

511-6-1.07(3)(a) – handwashing cleanser, availability (pf)

Points: 4

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed no handsoap at both handsinks. (3) Numbers and Capacities. (a) Handwashing Cleanser, Availability. Each handwashing sink or group of two adjacent handwashing sinks shall be provided with a supply of hand cleaning liquid, powder, or bar soap. EHS informed the PIC of the need to supply the handsinks with soap.

Violation #3:

2-2D – adequate handwashing facilities supplied & accessible

511-6-1.07(3)(b) – hand drying provision (pf)

Points: 4

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed no paper towels at the back handsink. (b) Hand Drying Provision. Each handwashing sink or group of adjacent handwashing sinks shall be provided with: 1. Individual, disposable towels; Pf 2. A continuous towel system that supplies the user with a clean towel; Pf 3. A heated-air hand drying device; Pf or 4. A hand drying device that employs an air-knife system that delivers high velocity, pressurized air at ambient temperatures. EHS informed the PIC of the need to supply the handsinks with paper towels.

Violation #4:

2-2D – adequate handwashing facilities supplied & accessible

511-6-1.06(2)(o) – using a handwashing sink- operation & maintenance (pf)

Points: 4

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed back handsink blocked by trashcan and mop bucket. (o) Using a Handwashing Sink. 1. A handwashing sink shall be maintained so that it is accessible at all times for employee use. Pf 2. A handwashing facility may not be used for purposes other than handwashing. EHS informed the PIC that the handsink can not be blocked.

Violation #5:

2-2E – response procedures for vomiting & diarrheal events

511-6-1.03(6) – clean-up of vomiting and diarrheal events(pf)

Points: 4

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed facility without a proper bodily fluid kit; facility has some supplies. (6) Responding To Contamination Events. A food establishment shall have written procedures for employees to follow and an EPA registered disinfectant effective against Norovirus available on-site at the food service establishment when responding to vomiting or diarrheal events that involve the discharge of vomitus or fecal matter onto surfaces in the food service establishment. The procedures shall address the specific actions employees must take to minimize the spread of contamination and the exposure of employees, consumers, food, and surfaces to vomitus or fecal matter. EHS informed the PIC of the need to purchase a bodily fluid kit or an absorbent to add to the supplies they already have.

Violation #6:

6-1A – proper cold holding temperatures

511-6-1.04(6)(f) – time/temperature control for safety; cold holding (p)

Points: 9

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed items in the prep top were above 41F. (f) Time/Temperature Control for Safety Food, Hot and Cold Holding. Except during preparation, cooking, or cooling, or when time is used as the public health control, time/temperature control for safety food shall be maintained at 41°F (5°C) or below. EHS informed the PIC to place all of the items on an ice bath as the unit is not maintaining temperature.

Violation #7:

14C – single-use/single-service articles: properly stored, used

511-6-1.05(6)(r) – single-service/single-use articles, use limitations (c)

Points: 1

Corrected during inspection?: No

Repeat: Yes

Inspector Notes: Observed facility re-using boxes to line equipment and storing an excess of soy sauce buckets. (r) Single-Service and Single-Use Articles, Use Limitation. 1. Single-service and single-use articles may not be reused. EHS informed PIC of the need to discard items once the original product is gone.

Violation #8:

15A – food and nonfood-contact surfaces cleanable, properly designed, constructed, and used

511-6-1.05(6)(q)1&3 – good repair & calibration (c)

Points: 1

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed the prep top cooler was not maintaining temperature. 3. Ambient air temperature, water pressure, and water temperature measuring devices shall be maintained in good repair and be accurate within the intended range of use. EHS informed the PIC to have the unit serviced ASAP. PIC contacted the individual to repair the unit while EHS was finishing the inspection. All items in the unit are to be placed on an ice bath.

Violation #9:

15C – nonfood-contact surfaces clean

511-6-1.05(7)(d) – nonfood-contact surfaces (c)

Points: 1

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed facility’s need to clean all equipment, including storage racks in the cooler/freezer and the condenser unit in the walk in cooler(heavy build -up present). (d) Nonfood-Contact Surfaces. Nonfood-contact surfaces of equipment shall be cleaned at a frequency necessary to preclude accumulation of soil residues. EHS informed the PIC of the need to clean all equipment.

Violation #10:

16B – plumbing installed; proper backflow devices

511-6-1.06(2)(r) – system maintained in good repair (p, c)

Points: 2

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed damaged plumbing to back handsink in the kitchen; water pouring on floor. (r) System Maintained in Good Repair. A plumbing system shall be repaired according to law; P and maintained in good repair. EHS informed the PIC of the need to repair the plumbing.

Violation #11:

17C – physical facilities installed, maintained, and clean

511-6-1.07(5)(a),(b) – good repair, physical facilities maintained; cleaning, frequency & restrictions, cleaned often enough to keep them clean (c)

Points: 1

Corrected during inspection?: No

Repeat: Yes

Inspector Notes: Observed ceiling tiles damaged, missing and/or in need of cleaning from dust accumulation. (5) Maintenance and Operation. (a) Good Repair. All physical facilities shall be maintained in good repair. (b) Cleaning, Frequency and Restrictions. 1. The physical facilities shall be cleaned as often as necessary to keep them clean and by methods that prevent contamination of food products. 2. Except for cleaning that is necessary due to a spill or other accident, cleaning shall be done during periods when the least amount of food is exposed, such as after closing. EHS informed the PIC of the need to clean and/ replace any damaged/missing ceiling tiles.

Violation #12:

17C – physical facilities installed, maintained, and clean

511-6-1.07(5)(a),(b) – good repair, physical facilities maintained; cleaning, frequency & restrictions, cleaned often enough to keep them clean (c)

Points: 1

Corrected during inspection?: No

Repeat: Yes

Inspector Notes: Observed facility in need of deep cleaning; cobb webbs throughout the facility. (b) Cleaning, Frequency and Restrictions. 1. The physical facilities shall be cleaned as often as necessary to keep them clean and by methods that prevent contamination of food products. 2. Except for cleaning that is necessary due to a spill or other accident, cleaning shall be done during periods when the least amount of food is exposed, such as after closing. EHS informed the PIC of the need to deep clean the facility.

Violation #13:

17C – physical facilities installed, maintained, and clean

511-6-1.07(5)(a),(b) – good repair, physical facilities maintained; cleaning, frequency & restrictions, cleaned often enough to keep them clean (c)

Points: 1

Corrected during inspection?: No

Repeat: Yes

Inspector Notes: Observed damaged wall near framing around the men restroom. 5) Maintenance and Operation. (a) Good Repair. All physical facilities shall be maintained in good repair. EHS informed the PIC of the need to have the area repaired as it is separating at the seam, creating an opening greater than an inch.

Violation #14:

17C – physical facilities installed, maintained, and clean

511-6-1.07(5)(a),(b) – good repair, physical facilities maintained; cleaning, frequency & restrictions, cleaned often enough to keep them clean (c)

Points: 1

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed potential sewage odor coming from ladies restroom. (5) Maintenance and Operation. (a) Good Repair. All physical facilities shall be maintained in good repair. (b) Cleaning, Frequency and Restrictions. 1. The physical facilities shall be cleaned as often as necessary to keep them clean and by methods that prevent contamination of food products. 2. Except for cleaning that is necessary due to a spill or other accident, cleaning shall be done during periods when the least amount of food is exposed, such as after closing. EHS informed the PIC of the need to address the issue.

Violation #15:

17D – adequate ventilation and lighting; designated areas used

511-6-1.07(4)(b) – designated areas for employee activity, located to prevent contamination of food, equipment, utensils, linens, & single service articles (c)

Points: 1

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed personal items stored in various places throughout the facility. (b) Designated Areas for Employee Activity. 1. Areas designated for employees to eat, drink, use tobacco products and electronic devices shall be located so that food, equipment, linens, and single-service and single-use articles are protected from contamination. 2. Lockers or other suitable facilities shall be located in a designated room or area where contamination of food, equipment, utensils, linens and single-service and single-use articles cannot occur. EHS informed the PIC of the need to create a designated area for employee belongings away from food prep and storage.

Violation #16:

18 – insects, rodents, and animals not present

511-6-1.07(2)(m) – outer openings protected (c)

Points: 3

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed light present between the front doors. (m) Outer Openings, Protected. 1. Except as specified in paragraphs 2 through 5 of this subsection, outer openings of a food service establishment shall be protected against the entry of insects and rodents by: (i) Filling or closing holes and other gaps along floors, walls, and ceilings; (ii) Closed, tight-fitting windows; and (iii) Solid, self-closing, tight-fitting doors. 2. The requirements in paragraph 1 of this subsection does not apply if a food service establishment opens into a larger structure, such as a mall, airport, or office building, or into an attached structure, such as a porch, and the outer openings from the larger or attached structure are protected against the entry of insects and rodents. 3. Exterior doors used as exits need not be self-closing if they are: (i) Solid and tight-fitting; (ii) Designated for use only when an emergency exists, by the fire protection authority that has jurisdiction over the food establishment; and (iii) Limited-use so they are not used for entrance or exit from the building for purposes other than the designated emergency exit use. 4. Except as specified in paragraphs 2 and 5 of this subsection, if the windows or doors of a food service establishment, or of a larger structure within which a food service establishment is located, are kept open for ventilation or other purposes or a temporary food service establishment is not provided with windows and doors as specified under paragraph 1 of this subsection, the openings shall be protected against the entry of insects and rodents by: (i) 16 mesh to 1 inch (16 mesh to 25.4 mm) screens; (ii) Properly designed and installed air curtains to control flying insects; or (iii) Other effective means. 5. The requirement in paragraph 4 of this subsection does not apply if flying insects and other pests are absent due to the location of the establishment, the weather, or other limiting condition. EHS informed the PIC of the need to install new weather stripping between the doors.

Additional remarks:

Items in prep unit were pulled from bulk containers in the walk in cooler.

CLICK HERE to read the full report