Remove ads by Supporting Independent News

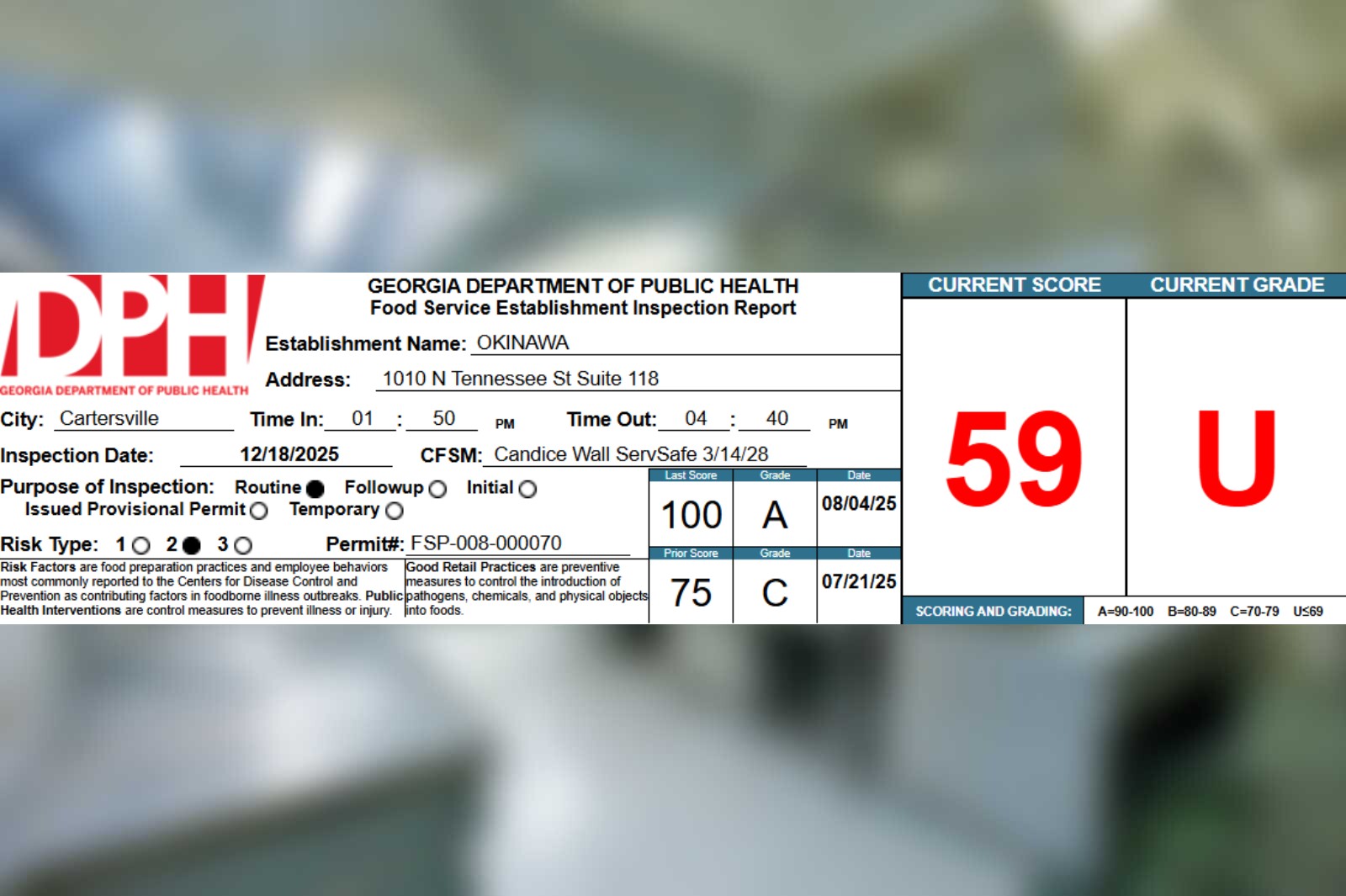

Okinawa, located at 1010 N Tennessee St Suite 118 in Cartersville, received a score of 59 points out of a possible 100 points during their 12/18/2025 inspection by the Georgia Department of Public Health.

The violations noted by the inspector were:

Violation #1:

1-2A – pic present, demonstrates knowledge, performs duties

511-6-1.03(1)(a)-(c)1,4,5,6-14,15, 16 – demonstration of knowledge (pf)

Points: 4

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed PIC lacking knowledge of foodborne illness risk factors. CA: PIC knowledge can be demonstrated by having no violations of Priority Items during routine inspections. CA: Employees need to be trained/re-trained. Health department-led training offered.

Violation #2:

1-2B – certified food protection manager

511-6-1-.03(3)(d) – certified food safety manager responsibility

Points: 4

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed certified food safety manager not fulfilling duties; unable to assess training needs of employees. CA: The responsibility of the CFSM shall include the safety of food preparation and service by ensuring that all employees who handle, or have responsibility for handling, unpackaged foods of any kind, have sufficient knowledge of safe preparation and service of the food. The nature and extent of the knowledge that each employee is required to have may be tailored, as appropriate, to the employee’s duties related to food safety issues. COS: Re-train CFSM. Health dept training offered.

Violation #3:

2-2B – proper eating, tasting, drinking, or tobacco use

511-6-1.03(5)(k)1&2 – eating, drinking, or using tobacco (c)

Points: 4

Corrected during inspection?: Yes

Repeat: Yes

Inspector Notes: Observed employee drinks stored in the kitchen without straws and stored on a food prep table. CA: Employee personal drinks stored in the kitchen shall be in a single use cup with lid and straw and handled/stored to prevent contamination. COS: Discussed with PIC that straws must be added and not stored on prep table.

Violation #4:

4-1A – food separated and protected

511-6-1.04(4)(c)1(i)(ii)(iii)(v)(vi)(vii)(viii) – packaged & unpackaged food separation, packaging, and segregation (p, c)

Points: 9

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed bowl with raw egg stored directly on top of pan of fully cooked steak in the prep top cooler. CA: Raw animal foods shall be stored based on their minimum internal cook temp and separately from ready-to-eat/fully cooked foods. COS: PIC removed the bowl with the egg.

Violation #5:

4-2A – food stored covered

511-6-1.04(4)(c)1(iv) – packaged & unpackaged food, food stored covered(c)

Points: 4

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed prepped salads stored uncovered in the reach-in cooler. CA: Foods shall be stored covered to protect from overhead contamination. COS: PIC covered salads.

Violation #6:

4-2B – food-contact surfaces: cleaned & sanitized

511-6-1.05(6)(n) – manual and mechanical warewashing equipment, chemical sanitization-temperature, ph, concentration, hardness (p,pf)

Points: 4

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed mechanical chemical sanitizing ware washing machine with no sanitizer (0ppm on the inspector test strip) while actively in use for cleaning dishes. COS: Employee adjusted the chemicals and primed the tubing and machine was verified to be working properly.

Violation #7:

6-1A – proper cold holding temperatures

511-6-1.04(6)(f) – time/temperature control for safety; cold holding (p)

Points: 9

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed improper cold holding of potentially hazardous TCS foods in ice baths, prep top coolers, reach-in coolers, and held on the countertop. See temp log for all foods and temperatures. CA: Cold held TCS foods shall maintain an internal temperature of 41F or below. COS: Per PIC, foods were out of temp for less than 4 hours and were moved to rapidly cool. Discussed keeping prep top lids closed when not in use and monitor temps.

Violation #8:

6-1B – proper hot holding temperatures

511-6-1.04(6)(f) – time/temperature control for safety; hot holding (p)

Points: 9

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed improper hot holding of potentially hazardous TCS foods stored on the counter (fried chicken, fried shrimp, crispy crab), fried rice in a rice cooker and teriyaki sauce on a hot plate and under a heat lamp. See temp log. CA: Hot held TCS foods shall maintain an internal temp of at least 135F or higher. COS: PIC chose to discard rice. All other foods were reheated to at least 165F.

Violation #9:

6-1D – time as a public health control: procedures and records

511-6-1.04(6)(i) – time as a public health control (tphc) (p, pf, c)

Points: 9

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed food labelled for 4 hour time as a public health control that did not start at 41F or lower or 135F or above when the initial time started; employee labelled egg wash mixture with time and mixture was 79F; fried shrimp and crispy crab were labelled with a start time and were at 72F and 74F. CA: If time without temperature control is used as the public health control up to a maximum of 4 hours, the food shall have an initial temp of 41F or less when removed from cold holding temp control or 135F or greater when removed from hot holding temp control. COS: Food was remade and start temps were verified upon labelling for TPHC.

Violation #10:

8-2B – toxic substances properly identified, stored, used

511-6-1.07(6)(b) – working containers, common name (pf)

Points: 4

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed several working spray bottles of chemicals that did not have a label to indicate the contents. CA: Working containers used for storing poisonous or toxic materials such as cleaners and sanitizers taken from bulk supplies shall be clearly and individually identified with the common name of the material. COS: PIC instructed employee to label all spray bottles.

Violation #11:

12B – personal cleanliness

511-6-1.03(5)(g) – jewelry (c)

Points: 3

Corrected during inspection?: Yes

Repeat: Yes

Inspector Notes: Observed several employees handling food while wearing watches. CA: Except for a plain ring such as a wedding band food employees may not wear jewelry including medical information jewelry on their arms and hands while preparing food. COS: PIC removed her watch and had the other employee remove his watch.

Violation #12:

12B – personal cleanliness

511-6-1.03(5)(j) – hair restraints (c)

Points: 3

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed employee handling food without a hair restraint. CA: Employees preparing or handling food shall use effective and clean, disposable or easily cleanable nets or other hair restraints approved by the Health Authority. COS: Unable to correct onsite. After discussing with the manager, the manager did not put a hair restraint on.

Violation #13:

12B – personal cleanliness

511-6-1.03(5)(f) – fingernails (pf)

Points: 3

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed employee handling food with painted while not wearing gloves. CA: Unless wearing gloves in good repair, a food employee may not wear fingernail polish or artificial fingernails when working with exposed food. COS: PIC put gloves on.

Violation #14:

17C – physical facilities installed, maintained, and clean

511-6-1.07(5)(a),(b) – good repair, physical facilities maintained; cleaning, frequency & restrictions, cleaned often enough to keep them clean (c)

Points: 1

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed surfaces throughout the facility (floors, walls, ceiling, exterior of equipment, hood vent) heavily soiled with grease. CA: Floors/walls/ceilings shall be maintained in good repair. COS: PIC will deep clean and moving forward increase frequency of routine cleaning.

Additional remarks:

Discussed with PIC:

-When to wash hands.

-Scoops in food must have handles; handles stored out of the food.

-Frozen food kept frozen prior to cooking (follow manufacturer storage requirements).

-Dry towels not used for wiping hands.

-Do no store knives in/on equipment that is not kept clean.

-Send specs for automatic sushi rice roller; rice must be temp or TPHC, food contact portion of machine must be cleaned/sanitized every 4 hours.

-Storage of personal items.

-Cooling methods

CLICK HERE to read the full report