Remove ads by Supporting Independent News

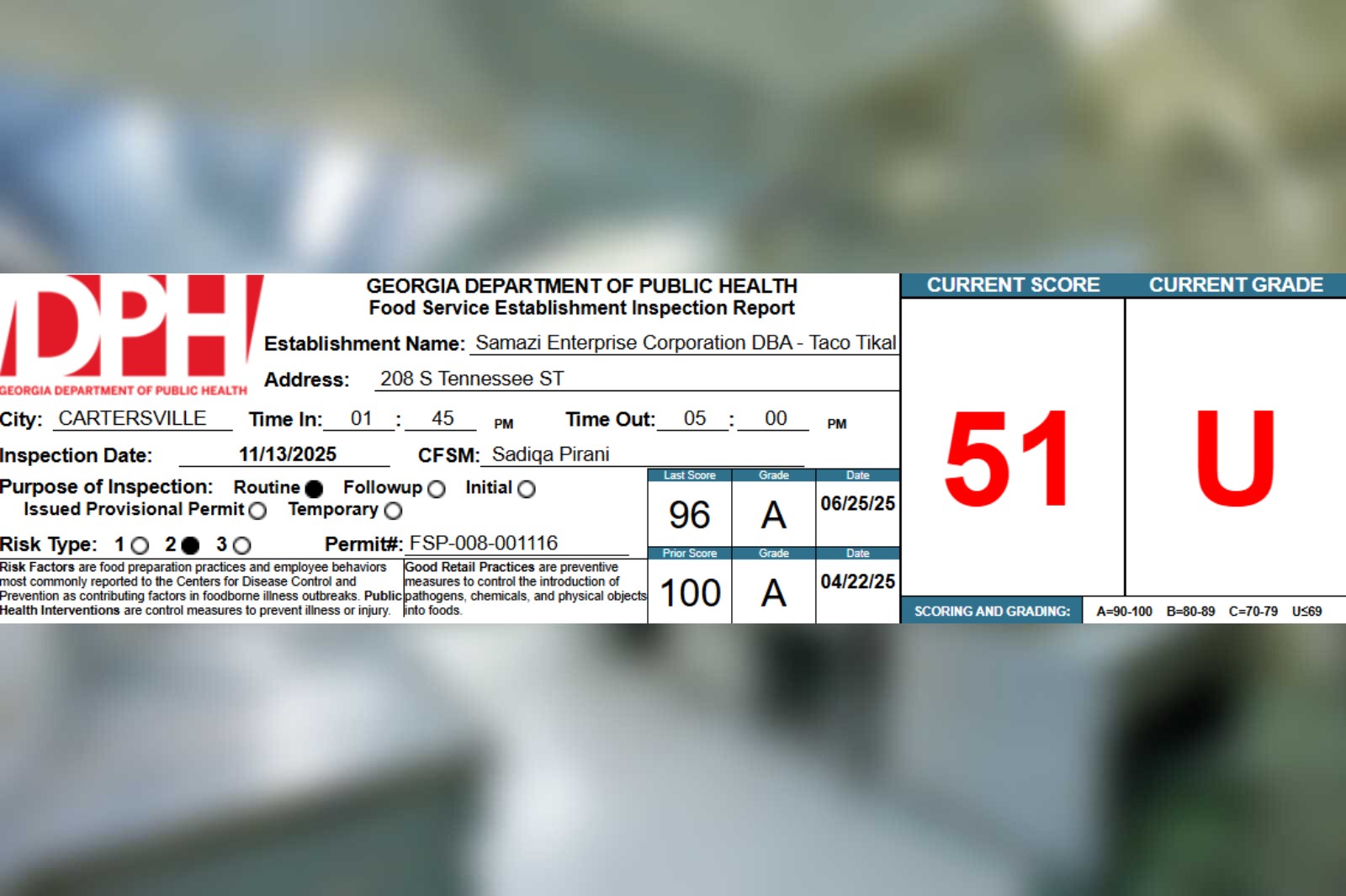

Samazi Enterprise Corporation DBA – Taco Tikal, located at 208 S Tennessee ST in Cartersville, received a score of 51 points out of a possible 100 points during their 11/13/2025 inspection by the Georgia Department of Public Health.

The violations noted by the inspector were:

Violation #1:

1-2A – pic present, demonstrates knowledge, performs duties

511-6-1.03(1)(a)-(c)1,4,5,6-14,15, 16 – demonstration of knowledge (pf)

Points: 4

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed unauthorized personnel in the kitchen preparing food; an employee of the attached (but separately permitted by the Department of Agriculture grocery store) was preparing food for personal consumption in the kitchen. CA: Persons unnecessary to the food service establishment operation are not allowed in the food preparation, food storage, or warewashing areas. COS: The unauthorized individual had left the kitchen, and discussed with the PIC that only employee can access the kitchen.

Violation #2:

1-2A – pic present, demonstrates knowledge, performs duties

511-6-1.03(1)(a)-(c)1,4,5,6-14,15, 16 – demonstration of knowledge (pf)

Points: 4

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed PIC lacking knowledge of foodborne illness risk factors. CA: PIC knowledge can be demonstrated by having no violations of Priority Items during routine inspections. CA: Employees need to be trained/re-trained.

Violation #3:

1-2B – certified food protection manager

511-6-1-.03(3)(d) – certified food safety manager responsibility

Points: 4

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed certified food safety manager not fulfilling duties; unable to assess training needs of employees. CA: The responsibility of the CFSM shall include the safety of food preparation and service by ensuring that all employees who handle, or have responsibility for handling, unpackaged foods of any kind, have sufficient knowledge of safe preparation and service of the food. The nature and extent of the knowledge that each employee is required to have may be tailored, as appropriate, to the employee’s duties related to food safety issues. COS: Re-train CFSM. Health dept training offered.

Violation #4:

2-1B – hands clean and properly washed

511-6-1.03(5)(c) – when to wash (p)

Points: 9

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed employee handle wet sanitizer rag to wipe counter with gloved hands, then change gloves without washing hands, then begin reheating rice on the stove. CA: Employees shall clean their hands and exposed portion of their arms immediately before engaging in food preparation before donning gloves to initiate a task that involves working with food and after engaging in other activities that contaminate the hands. COS: Instructed employee to stop cooking, remove gloves, wash hands, then don a clean pair of gloves.

Violation #5:

2-2A – management knowledge, responsibilities, reporting

511-6-1.03(4)(a)(b)(c)(e)(f) – responsibility of permit holder, pic, and conditional employees (p), (pf)

Points: 4

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed person-in-charge unable to demonstrate that employees have been trained on employee health; signed documentation is unavailable for any employee and PIC was unable to list all reportable symptoms and illnesses. CA: CA: PIC must provide documentation or otherwise satisfactorily demonstrate that all food employees and conditional employees are informed of their responsibilities to report to management information about their health and activities as it relates to diseases that are transmissible through food.

Violation #6:

2-2D – adequate handwashing facilities supplied & accessible

511-6-1.07(3)(a) – handwashing cleanser, availability (pf)

Points: 4

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed no hand cleanser available at the front hand wash sink or the back hand wash sink. CA: Each hand wash sink shall be supplied with hand cleanser. COS: PIC moved hand soap to the sinks.

Violation #7:

2-2D – adequate handwashing facilities supplied & accessible

511-6-1.07(3)(b) – hand drying provision (pf)

Points: 4

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed no hand drying provisions at either hand wash sink in the front and back kitchen areas. CA: All hand wash sinks shall be provided with an approved means of drying hands. COS: PIC moved napkins near each sink. Paper towel dispenser need to be fixed/put back on to the walls.

Violation #8:

2-2D – adequate handwashing facilities supplied & accessible

511-6-1.06(2)(o) – using a handwashing sink- operation & maintenance (pf)

Points: 4

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed clean dishes air drying in the back handwash sink. CA: Handwashing sinks shall be used for washing hands only. COS: PIC had employee move the dishes.

Violation #9:

2-2E – response procedures for vomiting & diarrheal events

511-6-1.03(6) – clean-up of vomiting and diarrheal events(pf)

Points: 4

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed no bodily fluid clean up kit or written procedure available in the facility. PIC did not have knowledge on procedure for safely cleaning a biohazardous spill. CA: A food establishment shall have written procedures for employees to follow and an EPA registered disinfectant effective against Norovirus available on-site at the food service establishment when responding to vomiting or diarrheal events that involve the discharge of vomitus or fecal matter onto surfaces in the food service establishment.

Violation #10:

4-1A – food separated and protected

511-6-1.04(4)(c)1(i)(ii)(iii)(v)(vi)(vii)(viii) – packaged & unpackaged food separation, packaging, and segregation (p, c)

Points: 9

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed improper separation of raw and ready-to-eat foods throughout the facility (raw chicken stored on top of raw beef in the prep top cooler, raw eggs stored above cooked beef in the reach-in cooler, raw eggs and raw chicken stored above produce in the walk-in cooler). CA: Raw animals foods shall be stored based on minimum internal cook temperatures. COS: PIC rearranged all coolers.

Violation #11:

4-2A – food stored covered

511-6-1.04(4)(c)1(iv) – packaged & unpackaged food, food stored covered(c)

Points: 4

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed multiple containers of food store uncovered in the kitchen; uncovered container of sugar had an electrical plug fall into the container and was submerged in the sugar. CA: While not in use food shall be stored covered to protect from overhead contamination. COS: PIC covered foods. Sugar was discarded.

Violation #12:

4-2B – food-contact surfaces: cleaned & sanitized

511-6-1.05(7)(a)1 – equipment, food-contact surfaces,& utensils (pf)

Points: 4

Corrected during inspection?: No

Repeat: Yes

Inspector Notes: Observed interior of ice machine and soda nozzle with black build up. CA: Equipment food contact surfaces and utensils shall be clean to sight and touch. COS: PIC stated ice machine will be drained and cleaned, all soda nozzles pulled for cleaning.

Violation #13:

4-2B – food-contact surfaces: cleaned & sanitized

511-6-1.05(8)(a) – before use after cleaning(p)

Points: 4

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed dishes being manually washed at the three compartment sink with soap and rinsing only; approved sanitizer was not in use. PIC stated they wash with dish soap, rinse, then air dry. CA: Utensils and food-contact surfaces of equipment shall be sanitized before use after cleaning. COS: PIC instructed employee to fill sanitize compartment of 3-comp sink with a chorine bleach solution. Verified correct concentration on inspector test strip.

Violation #14:

6-1A – proper cold holding temperatures

511-6-1.04(6)(f) – time/temperature control for safety; cold holding (p)

Points: 9

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed improper cold holding of all potentially hazardous TCS foods in the prep top cooler, and all foods in the walk-in cooler (see temp log). CA: All cold held TCS foods shall maintain an internal temperature of 41F or lower. COS: Per PIC, foods in prep top cooler had been out of temp for less than 4 hours and were moved to a different cooler to rapidly cool. All foods in the walk-in cooler were at 43F, but ambient cooler temp was 38F. PIC stated a delivery had been received and walk-in door and air curtains had been propped open. PIC to monitor food temps to ensure all food reaches 41F.

Violation #15:

6-1B – proper hot holding temperatures

511-6-1.04(6)(f) – time/temperature control for safety; hot holding (p)

Points: 9

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed rice in warmer at 75F. CA: Hot held potentially hazardous TCS foods shall maintain an internal temperature of 135F or above. COS: PIC stated food was out of temp for less than 4 hours and had employee reheat rice to above 165F.

Violation #16:

6-2 – proper date marking and disposition

511-6-1.04(6)(g) – ready-to-eat time/temperature control for safety food, date marking (pf)

Points: 4

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed several house made/opened TCS foods that were prepped on a previous day and did not bear an expiration date (hot dogs, queso, heavy cream, cooked beef, curry sauce). CA: TCS foods that require date marking and that are not used within 24 hours of opening/prep shall be consumed or discarded after 7 days. COS: PIC discarded foods.

Violation #17:

8-2B – toxic substances properly identified, stored, used

511-6-1.07(6)(b) – working containers, common name (pf)

Points: 4

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed unlabeled working spray bottles of a toxic substance. CA: Working containers used for storing poisonous or toxic materials such as cleaners and sanitizers taken from bulk supplies shall be clearly and individually identified with the common name of the material. COS: PIC labelled.

Additional remarks:

Discussed the following with the person-in-charge:

-Date marking procedure (7 days, day of opening/prep = day 1).

-Label all working containers of food and spices.

-Personal hygiene (hair restraints).

-Hot water at the front hand sink.

-Employee personal drinks.

-Storage of wet rags

-Sanitizer test strips

-Proper thawing.

-Frozen food stored frozen until cooked.

-Display permit (copy given).

-Food stored off the floor.

-Discontinue buffet until health department approval.

-Cooling methods.

-Internal thermometers in all coolers.

-Self-closure on bathroom door.

-Storage of personal food in coolers.

-Food from unapproved sources should not be in the facility.

-No re-use of single use containers for food storage, not using plastic take out bags to store food.

-Scoops stored in foods must have handle.

-Dented cans

-Curtains used to cover dry storage shelving must be nonabsorbent.

-All finishes (floors/walls/ceilings/coving) must be smooth/cleanable and in good repair.

-Weather stripping on back door.

CLICK HERE to read the full report