Remove ads by Supporting Independent News

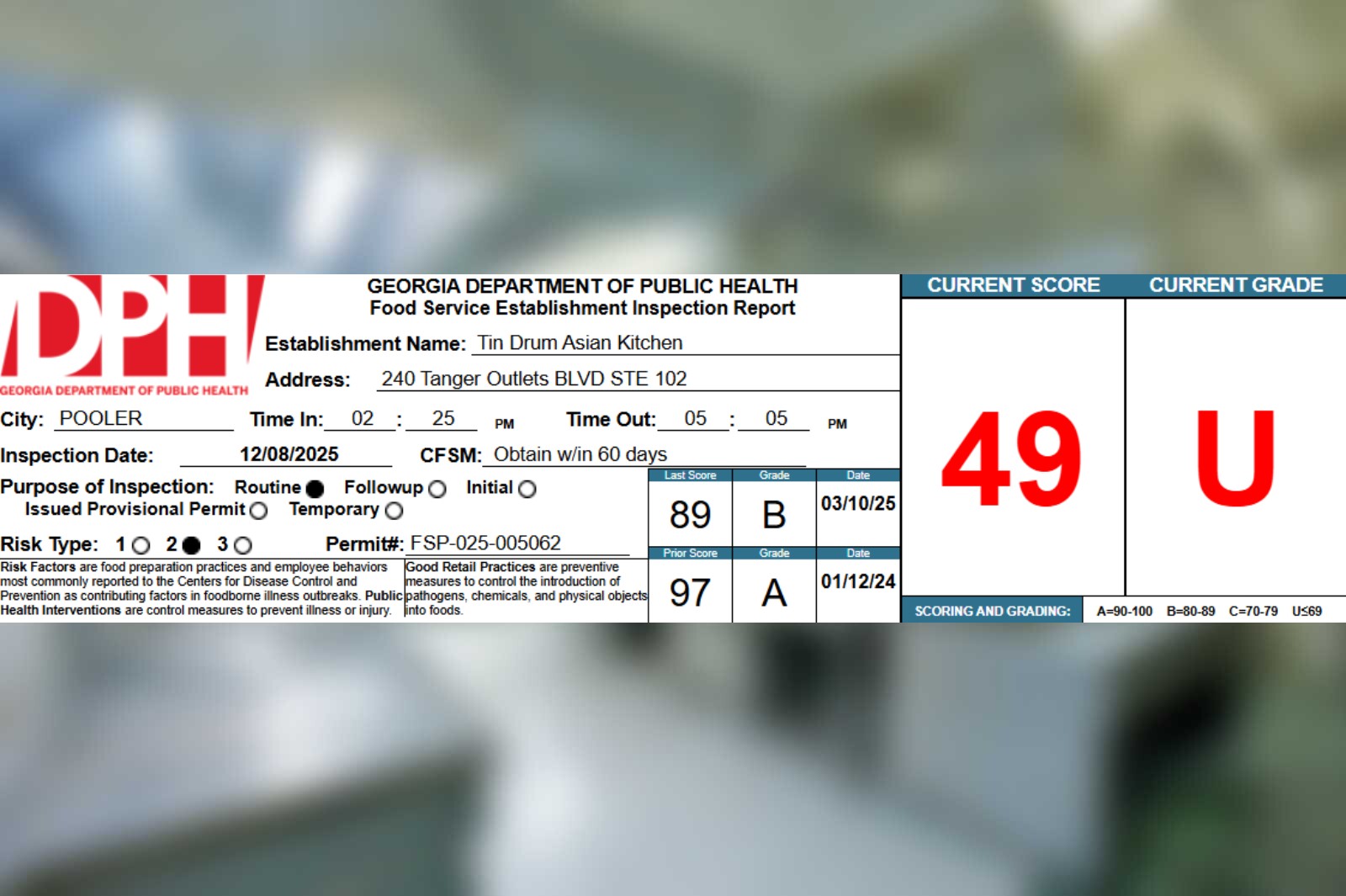

Tin Drum Asian Kitchen, located at 240 Tanger Outlets Blvd Ste 102 in Pooler, received a score of 49 points out of a possible 100 points during their 12/08/2025 inspection by the Georgia Department of Public Health.

The violations noted by the inspector were:

Violation #1:

1-2A – pic present, demonstrates knowledge, performs duties

511-6-1.03(2)(a)-(n)(p),(q) – responsibility of pic (pf)

Points: 4

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed an overall lack of active managerial control involving the following critical risk factors within the facility: Proper employee handwashing through access to functioning handwashing sinks, Proper hot holding temperatures for food, Proper sanitization of dishware and utensils, Proper separation of cooked and raw animal products. RCA: PIC shall ensure staff are following proper food safety training and techniques and implement procedures to verify methods.

Violation #2:

2-2D – adequate handwashing facilities supplied & accessible

511-6-1.06(2)(o) – using a handwashing sink- operation & maintenance (pf)

Points: 4

Corrected during inspection?: No

Repeat: Yes

Inspector Notes: Observed that handwashing sink in main kitchen area did not have hot water available. Observed that handwashing sink on drink station hot water only reach 80F. RCA: A handwashing sink shall be maintained so that it is accessible at all times for employee use. Hot water at handwashing stations shall reach 85F at minimum.

Violation #3:

4-1A – food separated and protected

511-6-1.04(4)(c)1(i)(ii)(iii)(v)(vi)(vii)(viii) – packaged & unpackaged food separation, packaging, and segregation (p, c)

Points: 9

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed cooked salmon stored under raw beef in reach-in cooler. COS CA: PIC rearranged foods. Cooked and raw animal foods shall be separated to prevent cross-contamination.

Violation #4:

4-2B – food-contact surfaces: cleaned & sanitized

511-6-1.05(6)(n) – manual and mechanical warewashing equipment, chemical sanitization-temperature, ph, concentration, hardness (p,pf)

Points: 4

Corrected during inspection?: No

Repeat: Yes

Inspector Notes: Observed the low temperature mechanical dishwasher was not pulling adequate amounts of chemical sanitizer. RCA: PIC shall not allow use of mechanical dishwasher until chemicals are replaced/refilled. Facility shall use 3-compartment sink for cleaning and sanitizing of dishware. After being cleaned, equipment food-contact surfaces and utensils shall be sanitized.

Violation #5:

6-1B – proper hot holding temperatures

511-6-1.04(6)(f) – time/temperature control for safety; hot holding (p)

Points: 9

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed chopped fried chicken in hot holding steam table at 121F. COS CA: PIC reheated chicken to 243F.

Violation #6:

6-2 – proper date marking and disposition

511-6-1.04(6)(g) – ready-to-eat time/temperature control for safety food, date marking (pf)

Points: 4

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed no date labeling of prepared ready-to-eat TCS foods (sauces, vegetables, precooked meats). TCS foods had been held over 24 hours but unable to tell exactly how long without date labeling. RC: Refrigerated, ready-to-eat, time/temperature control for safety food prepared and held in a food establishment for more than 24 hours shall be clearly marked to indicate the date or day by which the food shall be consumed on the premises, sold, or discarded, when held at a temperature of 41°F (5°C) or below for a maximum of 7 days. The day of preparation shall be counted as Day 1.

Violation #7:

9-2 – compliance with variance, specialized process and haccp plan

511-6-1.04(6)(k) – reduced oxygen packaging, criteria (p, pf)

Points: 4

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed facility was using Sous-vide to cook beef without a variance/HACCP plan and unable to articulate on processes. RCA: a food service establishment that packages food using a cook-chill or sous vide process shall: (i) Prior to implementation, provide a HACCP plan that contains the information as specified under DPH Rule 511-6-1-.02(8)(a)through(g) to the Health Authority; (ii) Ensure the food is: (I) Prepared and consumed on the premises, or prepared and consumed off the premises but within the same business entity with no distribution or sale of the bagged product to another business entity or the consumer, (II) Cooked to heat all parts of the food to a temperature and for a time as specified under DPH Rule 511-6-1-.04(5)(a), (III) Protected from contamination before and after cooking as specified within DPH Rule 511-6-1-.04 (4) and (5) of this Rule,(IV) Placed in a package with an oxygen barrier and sealed before cooking, or placed in a package and sealed immediately after cooking and before reaching a temperature below 135°F (57°C), (V) Cooled to 41°F (5°C) in the sealed package or bag as specified under DPH Rule 511-6-1-.04 (6) (d) of this Rule and subsequently: (A) Cooled to 34°F (1°C) within 48 hours of reaching 41°F (5°C) and held at that temperature until consumed or discarded within 30 days after the date of packaging; or (B) Held at 41°F (5°C) or less for no more than 7 days, at which time the food must be consumed or discarded; or (C) Cooled to 34°F (1°C) within 48 hours of reaching 41°F (5°C), removed from refrigeration equipment that maintains a 34°F (1°C) food temperature and then held at 41°F (5°C) or less for no more than 7 days, not to exceed 30 days from its date of packaging, at which time the food must be consumed or discarded; P or (D) Held frozen with no shelf life restriction while frozen until consumed or used. (VI) Held in a refrigeration unit that is equipped with an electronic system that continuously monitors time and temperature and is visually examined for proper operation twice daily, (VII) If transported off-site to a satellite location of the same business entity, equipped with verifiable electronic monitoring devices to ensure that times and temperatures are monitored during transportation, Pf and (VIII) Labeled with the product name and the date packaged, and (iii) Maintain the records required to confirm that cooling and cold holding refrigeration time/temperature parameters are required as part of the HACCP plan for at least six months and, make such records available to the Health Authority upon request, (iv) Implement written operational procedures as specified under paragraph 2(v) of this subsection and a training program as specified under paragraph 2(vi) of this subsection.

Violation #8:

11D – thermometers provided and accurate

511-6-1.05(2)(x) – tmd, located in refrigerators/ hot holding (pf, c)

Points: 3

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed that most cold holding units were missing internal thermometers. RCA: In a mechanically refrigerated or hot food storage unit, the sensor of a temperature measuring device shall be located to measure the air temperature in the warmest part of a mechanically refrigerated unit.

Violation #9:

12A – contamination prevented during food preparation, storage, display

511-6-1.04(4)(q) – food storage (c)

Points: 3

Corrected during inspection?: Yes

Repeat: Yes

Inspector Notes: Observed multiple boxes of oil on floor in main kitchen area. COS CA: MOD moved boxes onto dunnage racks. Food shall be protected from contamination by storing the food: In a clean, dry location; Where it is not exposed to splash, dust, or other contamination; and At least 6 inches above the floor.

Violation #10:

15B – warewashing facilities: installed, maintained, used; test strips

511-6-1.05(3)(h),(i),(j) – temperature measuring device, manual warewashing; sanitizing solutions, testing device (pf)

Points: 1

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed facility did not have quat test strips for 3-compartment sink sanitizer solution. RCA: A test kit or other device that accurately measures the concentration in mg/L of sanitizing solutions shall be provided.

Violation #11:

15C – nonfood-contact surfaces clean

511-6-1.05(7)(d) – nonfood-contact surfaces (c)

Points: 1

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed build-up on equipment(fryers, reach-in coolers, gaskets). RCA: Nonfood-contact surfaces of equipment shall be cleaned at a frequency necessary to preclude accumulation of soil residues.

Violation #12:

17D – adequate ventilation and lighting; designated areas used

511-6-1.07(3)(f) – lighting intensity, adequate in food prep, storage & service areas (c)

Points: 1

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed that 2 lights under hood were not functioning. RCA: The lighting intensity At least 50 foot candles (540 lux) at a surface where a food service employee is working with food or working with utensils or equipment such as knives, slicers, grinders, or saws where employee safety is a factor.

Violation #13:

17D – adequate ventilation and lighting; designated areas used

511-6-1.07(4)(b) – designated areas for employee activity, located to prevent contamination of food, equipment, utensils, linens, & single service articles (c)

Points: 1

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed employee items (coats) stored on top of dry pantry goods. COS CA: PIC moved items. Lockers or other suitable facilities shall be located in a designated room or area where contamination of food, equipment, utensils, linens and single-service and single-use articles cannot occur.

Additional remarks:

Management change since last inspection. MOD Robert Costello left inspection at approximately 3:30PM, continued inspection with employee Arcineo Bedeau.

Cold held food found above 41F had recently been in use and were within safe time limits.

Facility management is to appear for an informal hearing on Friday, December 12, 2025 at Environmental Health Office located at 1395 Eisenhower Dr. (building at the back of the main health department).

CLICK HERE to read the full report