Remove ads by Supporting Independent News

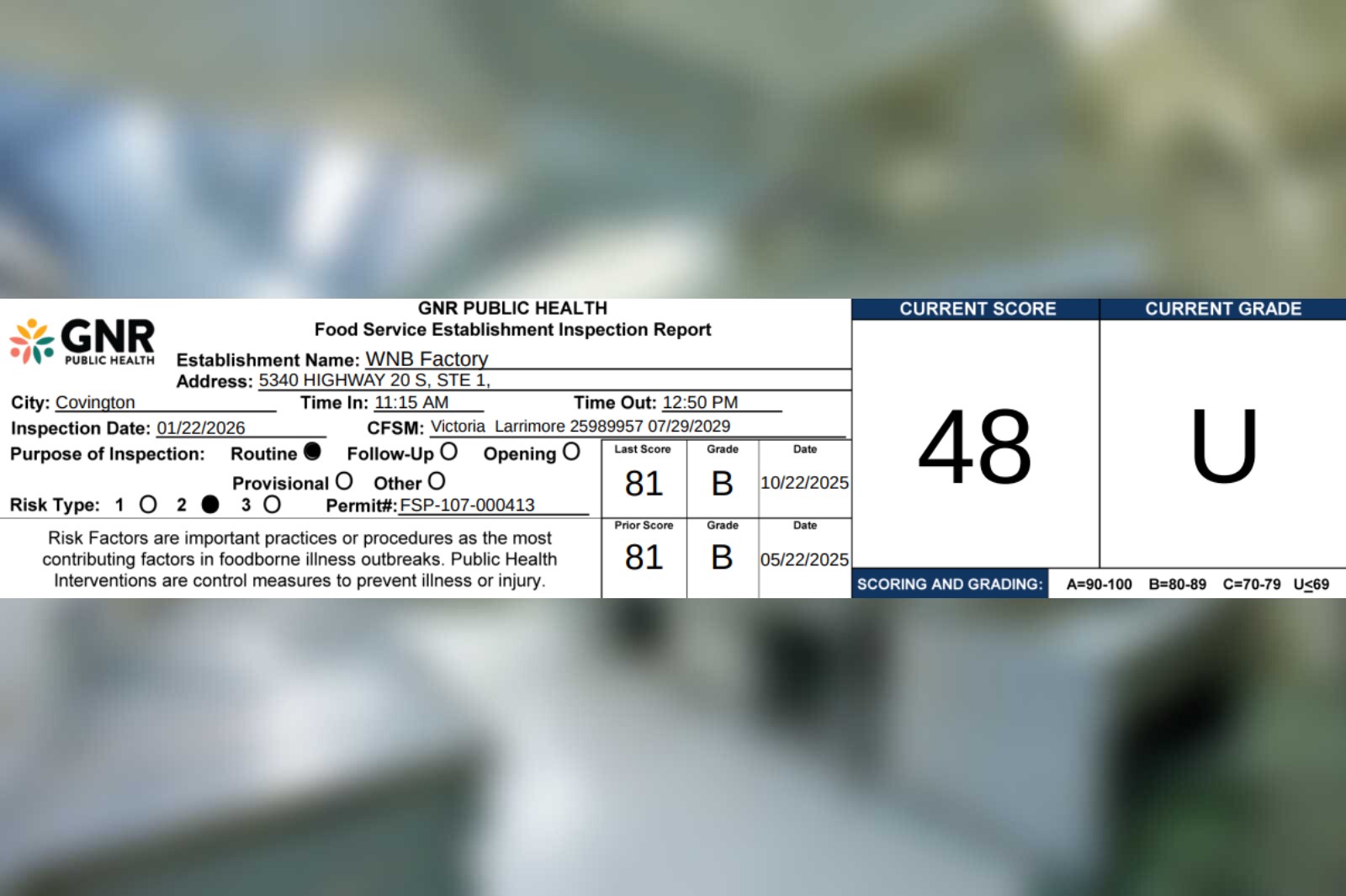

WNB Factory, located at 5340 Highway 20 S, Ste 1 in Covington, received a score of 48 points out of a possible 100 points during their 01/22/2026 inspection by the Georgia Department of Public Health.

The violations noted by the inspector were:

Violation #1:

1-2A: .03(2)(a)-(l), (n)Based on today’s routine inspection and the grade/score earned the facility lacks a person in charge to implement procedures and practices to ensure food safety and compliance with the Georgia Food rules and regulations. The person in charge must be able to demonstrate their food safety knowledge through full compliance of the food code with no violations, be a Certified Food Safety Manager, or be able to provide correct answers to food safety questions as they relate to the food service operation at hand. (Pf)

Corrective Actions: NCOS

Violation #2:

2-2D: .06(2)(g)Observed a spray bottle of degreaser being stored in the handsink. **This is a second consecutive repeat of the same code provision. A third repeat of the same code provision will result in permit suspension.** A handwashing facility may not be used for purposes other than handwashing. (Pf)

Corrective Actions: Person in Charge (PIC) removed the bottle of degreaser and EH educated employees on only using the hand sink for handwashing.

Violation #3:

4-1A: .04(4)(c)1(i)(ii)(iii)(v) (vi)(vii)(viii)Observed raw chicken being stored on the same shelf with raw beef, raw shrimp, and cooked chicken, cooked rice, and vegetables. Also observed raw chicken being stored on the bottom shelf with vegetables. Food shall be protected from cross contamination by: (i) Except as specified in paragraph (i)(III) of this subsection, separating raw animal foods during storage, preparation, holding, and display from: (I) Raw ready-to-eat food including other raw animal food such as fish for sushi or molluscan shellfish, or other raw ready-to-eat food such as fruits and vegetables, (P) and (II) Cooked ready-to-eat food; and (P) (III) Frozen, commercially processed and packaged raw animal food may be stored or displayed with or above frozen, commercially processed and packaged, ready-to-eat food. (ii) Except when combined as ingredients, separating types of raw animal foods from each other such as beef, fish, lamb, pork, and poultry during storage, preparation, holding, and display by: (I) Using separate equipment for each type, (P) or (II) Arranging each type of food in equipment so that cross contamination of one type with another is prevented, (P) and (III) Preparing each type of food at different times or in separate areas; (P) (iii) Cleaning and sanitizing equipment and utensils; (v) Cleaning hermetically sealed containers of food of visible soil before opening; (vi) Protecting food containers that are received packaged together in a case or overwrap from cuts when the case or overwrap is opened; (vii) Storing damaged, spoiled, or recalled food being held in the food service establishment separate from food, equipment, utensils, linens and single-service and single-use articles; or (viii) Separating fruits and vegetables, before they are washed from ready-to-eat food.

Corrective Actions: PIC rearranged the walk in cooler so that food items were stored properly.

Violation #4:

4-2A: .04(4)(c)1(iv)Observed where food items being stored in the reach in coolers and the walk in cooler were not being stored covered. The food items included raw chicken, appetizers, and vegetables. **This is the second consecutive repeat of the same code provision. A third repeat of the same code provision will result in permit suspension.** Food must be protected from cross contamination by storing the food in packages, covered containers, or wrappings, except for loosely covered, or uncovered containers in which food is being cooled if protected from overhead contamination. (C)

Corrective Actions: PIC covered food items.

Violation #5:

6-1C: .04(6)(d)Observed three containers of rice that has been prepared yesterday being stored in the walk in cooler that were 48-50 degrees in temperature. Cooling Rate: TCS foods being cooled from 135°F to 70°F in 2 hours MUST cool 0.54°F per minute (roughly 32.5°F per hour). To successfully cool from 135°F to 70°F within two hours, the food must be cooled at a rate of approximately 0.54°F per minute (135°F -70°F = 65°F total divided by 120 minutes = 0.54°F per minute) or 32.5°F per hour. TCS foods being cooled from 70°F to 41°F MUST cool 7.25°F per hour (29°F in 4 hours). To successfully cool from 70°F to 41°F within 4 hours, the food must be cooled at a rate of 0.121°F per minute (70-41 = 29°F total divided by 240 minutes = 0.121°F per minute) or 7.25°F per hour.

Corrective Actions: PIC discarded food items.

Violation #6:

6-1D: .04(6)(i)Observed chicken wings that were said to be placed on time control yesterday that were put in the walk in cooler to be used today. When using Time Control (TPHC) for a maximum of 4 hours: 1) hot foods shall start at 135°F (57°C) or above and cold foods shall start at 41°F (5°C) or below; (P) 2) the food items shall be labeled with a start and discard time, not to exceed 4 hours; (Pf) 3) foods not consumed before the discard time shall be discarded; (P) 4) when combining ingredients, the start/discard time for the foods shall reflect the start/discard time of the earliest ingredient placed on time control; {P) 5) food in unmarked containers or packages, or marked to exceed a 4-hour limit shall be discarded; (P) 6) written procedures TPHC shall be created in advance and made available upon the Health Authorities request. (Pf)

Corrective Actions: PIC discarded chicken wings. EH educated PIC on following time control procedures which is to discard any food items that are on time control after the 4 hour time has ended.

Violation #7:

6-2: .04(6)(g)Observed multiple food items such as cooked rice, cut tomatoes, prepped jalapenos, and coleslaw that did not have a date on which these items were prepped or a discard date. Refrigerated, ready-to-eat time/temperature control for safety foods prepared and held in a food establishment for more than 24-hours shall be clearly marked to indicate the date of prep or the date by with the food shall be used/discarded for a maximum of 7 days. The day of preparation shall be counted as Day 1. (Pf)

Corrective Actions: PIC discarded food items.

Violation #8:

8-2B: .07(6)(b)Observed a bottle of degreaser and other spray bottles holding chemicals that did not have names listed for what was being stored inside. Working containers used for storing poisonous or toxic materials such as cleaners and sanitizers taken from bulk supplies shall be clearly and individually identified with the common name of the material. (Pf)

Corrective Actions: PIC labeled the chemical bottles.

Violation #9:

11A: .04(6)(e)Observed multiple containers of rice that were cooked yesterday that were being stored in large, tightly fitted lids that had not cooled down properly. Foods shall be cooled using one or more methods approved by the health authority (i.e., small batches, thinner portions, ice wands, blast chillers, ice as an ingredient, placing in the walk-in cooler or walk-in freezer uncovered (or partially uncovered) as long as the food is protected from overhead contamination). (Pf, C)

Corrective Actions: EH educated PIC on proper cooling methods such as storing cooling items in shallow, loosely covered, containers.

Violation #10:

14A: .04(4)(k)Observed multiple utensils being stored with the handles in the products. Items included cooked rice and sugar. **This is a second consecutive repeat of the same code provision. A third repeat of the same code provision will result in permit suspension.** During pauses in food preparation or dispensing, food preparation and dispensing utensils shall be stored: 1. in the food with their handles above the top of the food and the container; 2. in running water of sufficient velocity to flush particulates to the drain, if used with moist food such as ice cream or mashed potatoes; 3. in a clean, dry container; or 4. in a container of water if the water is maintained at a temperature of at least 135°F (57°C) and the container is cleaned at the required frequency. (C)

Corrective Actions: PIC removed the handles from the products

Violation #11:

18: .07(2)(m)Observed the backdoor of the facility was being left opened. Outer openings of a food service establishment shall be protected against the entry of insects and rodents by: 1) filling or closing holes and other gaps along floors, walls, and ceilings; (C) 2) closed, tight-fitting windows; (C) and 3) solid self-closing, tight-fitting doors. (C)

Corrective Actions: PIC closed the back door of the facility.

Additional remarks:

All cold holding and hot held temperatures were in compliance.

All frozen foods were frozen solid.

A follow up inspection will be conducted on or before January 30th, 2026. Any violations that were not corrected during today’s inspection must be correct or the facility’s permit will be suspended and service must cease until all violations are corrected.

Note: A third repeat of the same code provision will result in permit suspension.

CLICK HERE to read the full report