Remove ads by Supporting Independent News

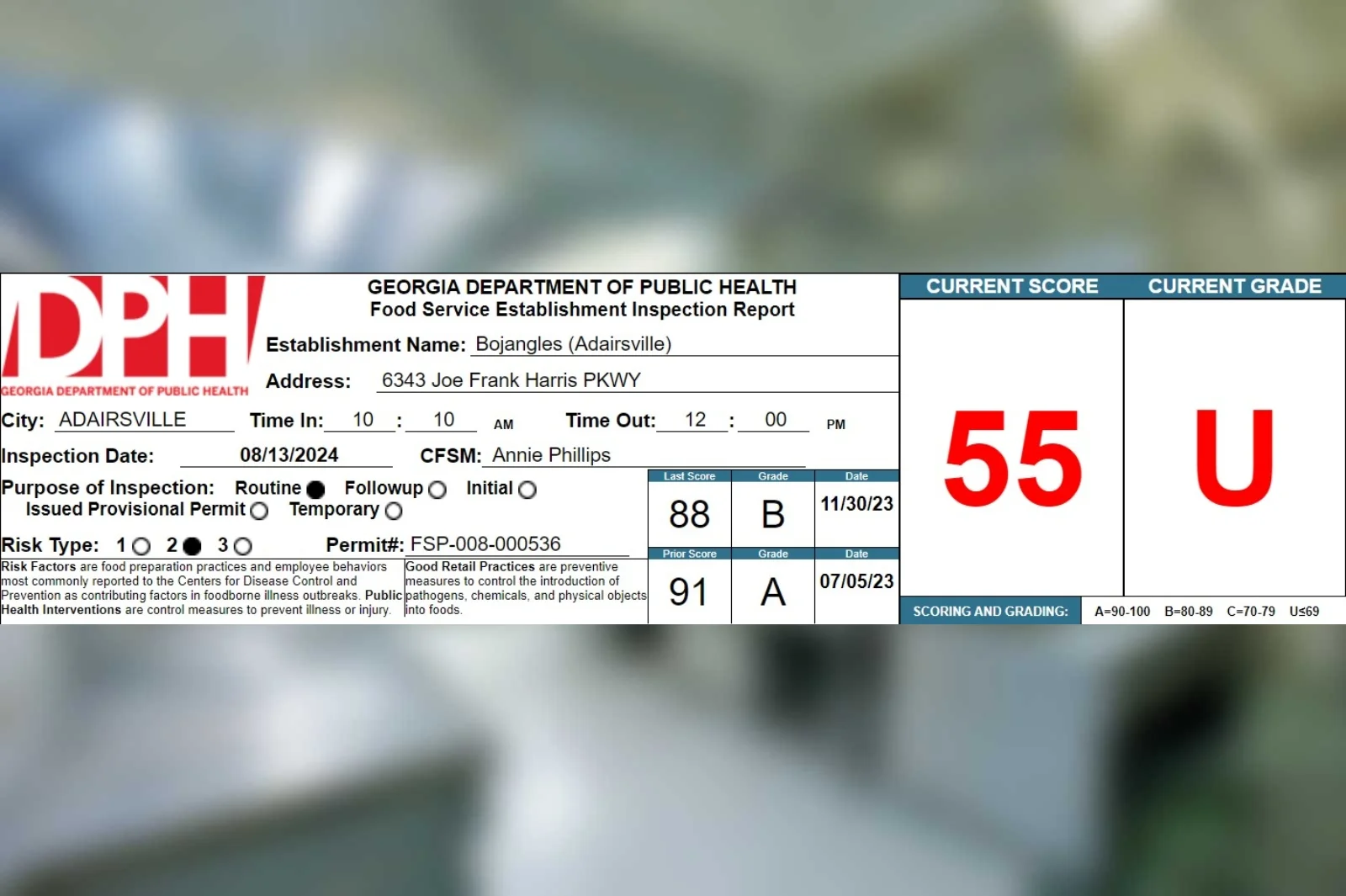

Bojangles (Adairsville), located at 6343 Joe Frank Harris Pkwy in Adairsville, received a score of 55 points out of a possible 100 points during their 08/13/2024 inspection by the Georgia Department of Public Health.

The violations noted by the inspector were:

Violation #1:

1-2A – pic present, demonstrates knowledge, performs duties

511-6-1.03(2)(a)-(l)(n)(o) – responsibility of pic (pf)

Points: 4

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed PIC not performing duties; employees are not properly trained in food safety as it relates to their duties and PIC is not monitoring to ensure safe food handling procedures are being followed. CA: All employees need to be properly trained or re-trained.

Violation #2:

1-2B – certified food protection manager

511-6-1-.03(3)(d) – certified food safety manager responsibility

Points: 4

Corrected during inspection?: No

Repeat: No

Inspector Notes: Certified Food Safety Manager does not demonstrate proficiency in active managerial control measures. CA: Persons in charge, managers or CFSM must be properly trained or retrained

Violation #3:

2-1B – hands clean and properly washed

511-6-1.03(5)(c) – when to wash (p)

Points: 9

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed employee come inside from having a cigarette outside, put clean gloves on and start handling food without first washing hands. CA: Discussed with PIC. Employee removed gloves, washed hands and put on clean gloves.

Violation #4:

2-2D – adequate handwashing facilities supplied & accessible

511-6-1.07(3)(a) – handwashing cleanser, availability (pf)

Points: 4

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed hand wash sink with no hand soap. CA: PIC refilled soap.

Violation #5:

2-2D – adequate handwashing facilities supplied & accessible

511-6-1.06(2)(o) – using a handwashing sink- operation & maintenance (pf)

Points: 4

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed scrubbing pad stored in the hand wash sink. CA: PIC relocated the scrubbing pad. Discussed that hand wash sinks must be used for hand washing only.

Violation #6:

2-2D – adequate handwashing facilities supplied & accessible

511-6-1.07(3)(b) – hand drying provision (pf)

Points: 4

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed paper towels not dispensing at the hand wash sink. CA: Battery needs to be changed or towels pulled through to allow for dispensing.

Violation #7:

4-1A – food separated and protected

511-6-1.04(4)(c)1(i)(ii)(iii)(v)(vi)(vii)(viii) – packaged & unpackaged food separation, packaging, and segregation (p, c)

Points: 9

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed improper vertical separation of raw animal food and ready-to-eat/fully cooked food in the walk-in cooler; batter dip for raw chicken (container had been used for battering raw chicken earlier and visible food accumulations from the raw chicken were on the interior and exterior of the container) was stored directly above pasteurized liquid egg. CA: PIC relocated the container of batter dip.

Violation #8:

4-1A – food separated and protected

511-6-1.04(4)(n)1 – gloves, use limitation (single use gloves) (p)

Points: 9

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed employee using a sanitizer cloth with gloved hands, then change tasks to handling food with the same gloves. CA: Employee removed gloves, washed hands then put new gloves on.

Violation #9:

6-1A – proper cold holding temperatures

511-6-1.04(6)(f) – time/temperature control for safety; cold holding (p)

Points: 9

Corrected during inspection?: Yes

Repeat: Yes

Inspector Notes: Observed potentially hazardous TCS foods (coleslaw, white milk, chocolate milk) improperly cold holding above 41F in the front reach-in cooler. CA: Coleslaw was discarded for a different violation and the milks were stocked in the unit less than 4 hours prior and were moved to the walk-in cooler to rapidly cool. Facility will not use the unit to hold TCS foods until it is serviced/repaired by a licensed technician and re-checked by health department.

Violation #10:

6-1B – proper hot holding temperatures

511-6-1.04(6)(f) – time/temperature control for safety; hot holding (p)

Points: 9

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed potentially hazardous TCS foods (mashed potatoes, pinto beans) improperly hot holding below 135F in the steam table by the drive thru). CA: Discussed with PIC. Food was out of temp for less than 4 hours. PIC chose to discard the mashed potatoes and the beans were re-heated to above 165F.

Violation #11:

11D – thermometers provided and accurate

511-6-1.05(2)(k) – temperature measuring device (tmd), food – accuracy (pf)

Points: 3

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed no internal food thermometer available in the facility. CA: Discussed with PIC. A thermometer will be purchased and utilized as soon as possible.

Violation #12:

11D – thermometers provided and accurate

511-6-1.05(2)(x) – tmd, located in refrigerators/ hot holding (pf, c)

Points: 3

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed no ambient air thermometer stored inside the reach-in cooler that had cold holding issues. CA: Discussed with PIC. All hot and cold holding units must have a thermometer placed in them.

Violation #13:

12A – contamination prevented during food preparation, storage, display

511-6-1.04(4)(z) – miscellaneous sources of contamination (c)

Points: 3

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed dark fiber or hair in a cup of coleslaw. CA: PIC discarded.

Violation #14:

17D – adequate ventilation and lighting; designated areas used

511-6-1.07(4)(b) – designated areas for employee activity, located to prevent contamination of food, equipment, utensils, linens, & single service articles (c)

Points: 1

Corrected during inspection?: Yes

Repeat: Yes

Inspector Notes: Observed employee personal items (purse, backpack) store on prep counters in front food service area. CA: PIC relocated personal items. Discussed requirement to have personal items stored in separate, designated areas.

Additional remarks:

Discussed the following with the person-in-charge:

-Live flies in the kitchen; increase frequency of routine pest control.

-Repair/replace tile around the fryer where oil is pooling and solidifying.

-Cooler drawers are not working. No food in them at time of inspection and per PIC a work order has been put in for their repair.

-Facility still needs to submit a written procedure for time as a public health control as requested in the previous routine inspection.

-Air drying clean dishes; no wet stacking.

-Storing tea jugs off the floor.

-Keeping employee bathroom door closed; self closure should be installed and door should not be propped open.

-Current inspection report must be publicly displayed; facility is drive thru only so report should be displayed at the drive thru where customers can view it.

-Food service permit and certification for the Certified Food Safety Manager need to be available in the facility.

-Walk-in freezer has excessive ice build up; deep clean and moving forward increase the frequency of routine cleaning.

-Employee health policy and reporting agreements: have available in the facility for health department review.

-Remove bracelets prior to washing hands and handling food.

-Cooling parameters and approved methods of cooling: 70F within 2 hours, 41 within 4 hours. Use an ice bath, shallow pans, lid uncovered/vented, freezer, etc.

-Facility does not have a produce prep sink and must use pre-washed produce until a separate, designated sink is installed.