Remove ads by Supporting Independent News

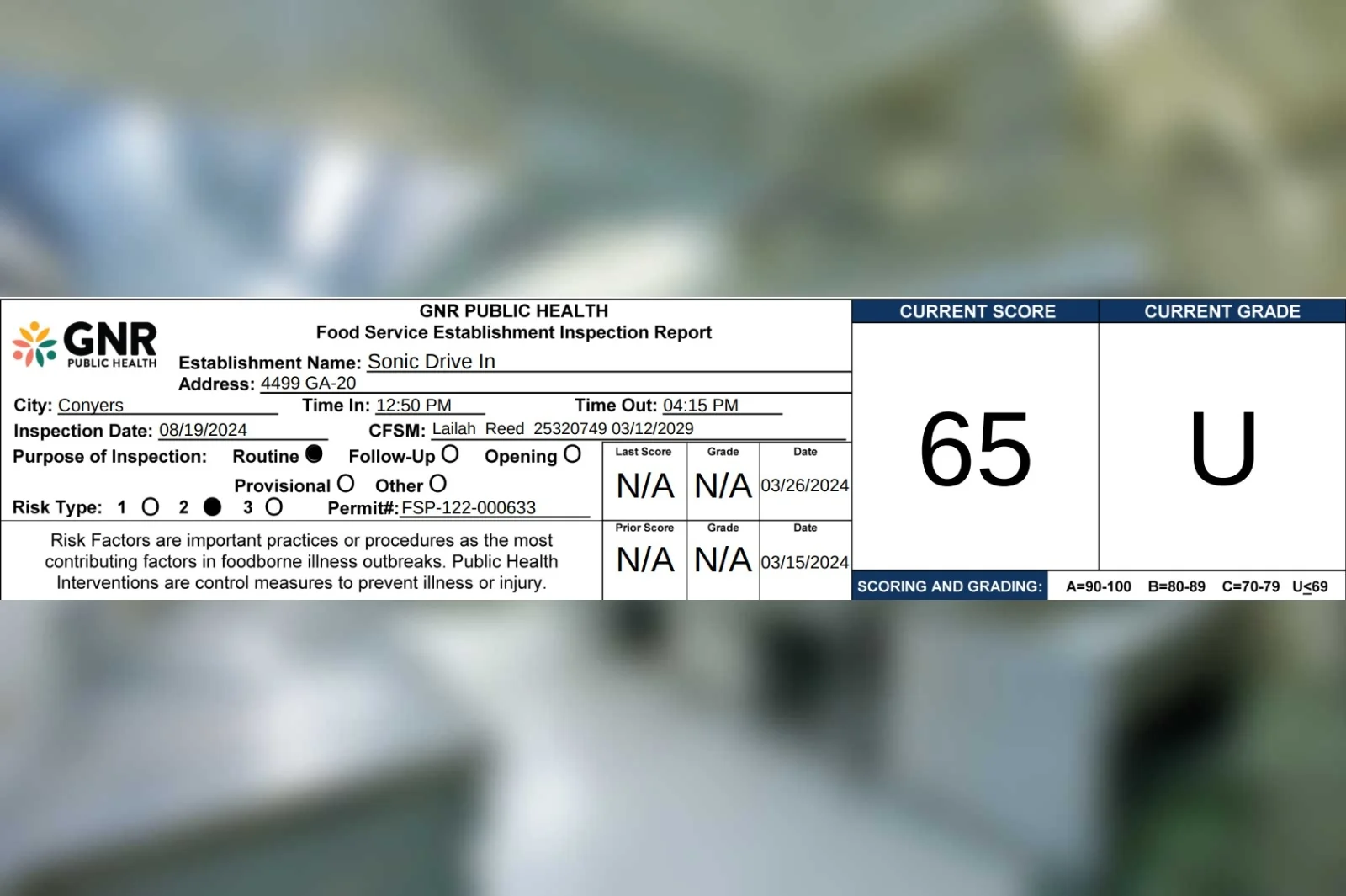

Sonic Drive In, located at 4499 GA-20 in Conyers, received a score of 65 points out of a possible 100 points during their 08/19/2024 inspection by the Georgia Department of Public Health.

The violations noted by the inspector were:

Violation #1:

1-2A: .03(2)(a)-(l), (n)Observed multiple violations. PIC(person in charge) does not have active managerial control. It is the responsibility of the person in charge to ensure compliance with the food code by demonstrating active managerial control within their facility. (Pf)

Violation #2:

2-2D: .03(5)(d)Observed food employee come in from outside and wash her hands in the three compartment sink located by the ice cream machine. Food employees shall clean their hands in a handwashing sink or approved automatic handwashing facility and may not clean their hands in a sink used for food preparation or warewashing, or in a service sink or curbed cleaning facility used for the disposal of mop water and similar liquid waste. (Pf)

Corrective Actions: PIC (person in charge) had food employee was her hands in a designated hand sink.

Violation #3:

4-1A: .04(4)(n)1Observed food employee place fanny pack around her waist and then proceeded to prep drinks without removing her soiled gloves and washing her hands. If used, single-use gloves shall be used for only one task such as working with ready-to-eat food or with raw animal food, used for no other purpose, and discarded when damaged or soiled, or when interruptions occur in the operation. (P)

Corrective Actions: Food employee removed the gloves, washed her hands, and then put on new gloves.

Violation #4:

6-1A: .04(6)(f)Observed lettuce, american cheese, and shredded cheese cold holding above 41F in the prep cooler. Prep cooler held ambient air of 60.1F. Observed pooled eggs, and raw bacon cold holding above 41F in the reach-in-cooler. Time/temperature control for safety food shall be maintained at 41°F (5°C) or below. (P)

Corrective Actions: PIC (person in charge) removed the lettuce, american cheese, shredded cheese, pooled eggs, and raw bacon to the walk-in-cooler.

Violation #5:

6-1C: .04(6)(d)Observed sliced tomatoes not cooling down in the prep cooler. Prep cooler held ambient air of 60.1F. Cooling Rate: TCS foods being cooled from 135°F to 70°F in 2 hours MUST cool 0.54°F per minute (roughly 32.5°F per hour). To successfully cool from 135°F to 70°F within two hours, the food must be cooled at a rate of approximately 0.54°F per minute (135°F -70°F = 65°F total divided by 120 minutes = 0.54°F per minute) or 32.5°F per hour. TCS foods being cooled from 70°F to 41°F MUST cool 7.25°F per hour (29°F in 4 hours). To successfully cool from 70°F to 41°F within 4 hours, the food must be cooled at a rate of 0.121°F per minute (70-41 = 29°F total divided by 240 minutes = 0.121°F per minute) or 7.25°F per hour.

Corrective Actions: PIC removes slice tomatoes to the reach in cooler.

Violation #6:

10D: .04(7)(d)Observed multiple squeeze bottles stored in the prep cooler and a container of oil not labeled. Except for containers holding food that can be readily and unmistakably recognized, such as dry pasta, working containers holding food or food ingredients that are removed from their original packages for use in the food establishment, such as cooking oils, flour, herbs, potato flakes, salt, spices, and sugar shall be clearly and legibly identified, in English, with the common name of the food. (C)

Corrective Actions: PIC labeled the squeeze bottles and the container of oil.

Violation #7:

11A: .04(6)(e)Observed slice tomatoes cooling in a prep cooler with ambient air of 60.1F. 1. Cooling shall be accomplished in accordance with the time and temperature criteria specified under DPH Rule 511-6-1-.04(6)(d) by using one or more of the following methods depending on the type of food being cooled: (i) Placing the food in shallow pans; (Pf) (ii) Separating the food into smaller or thinner portions; (Pf) (iii) Using rapid cooling equipment; (Pf) (iv) Stirring the food in a container placed in an ice water bath; (Pf) (v) Using containers that facilitate heat transfer; (Pf) (vi) Adding ice as an ingredient; (Pf) or (vii) Other effective methods. (Pf) 2. When placed in cooling or cold holding equipment, food containers in which food is being cooled shall be: (i) Arranged in the equipment to provide maximum heat transfer through the container walls; (C) and (ii) Loosely covered, or uncovered if protected from overhead contamination during the cooling period to facilitate heat transfer from the surface of the food. (C)

Corrective Actions: PIC removed the sliced tomatoes to the reach-in-cooler for rapid cooling.

Violation #8:

15A: .05(6)(a)Observed the prep cooler held ambient air of 60.1F. Observed shelving in the storage area rusty. Observed the walk-in-freezer fan with an accumulation of ice. Equipment shall be maintained in a state of repair and condition that meets the requirements specified under subsections (1) and (2)of this Rule. (C)

Violation #9:

15C: .05(7)(a)2,3Observed the following; 1. non food contact utensils used to store queso cheese and cooked hamburger patties containing food debris. 2.multiple non food contact metal utensil lids containing food debris. 3. non food contact surface metal top used to cover up the fryer containing food debris. 4. the bottom of the reach-in-cooler containing food debris. 5. reach-in-cooler gasket containing food debris. Nonfood-contact surfaces of equipment shall be kept free of an accumulation of dust, dirt, food residue, and other debris. (C)

Corrective Actions: PIC removed the queso cheese and hamburger patties to a clean container. PIC washed all of the utensils lids, reach-in-cooler, gaskets, and the metal top used to cover up the fryer.

Violation #10:

17B: .06(5)(n)Observed the lid on the side of the dumpster open. Observed the top lid on the dumpster open. Receptacles and waste handling units for refuse, recyclables, and returnables shall be kept covered. (C)

Corrective Actions: PIC closed the both lids.

Violation #11:

17B: .06(5)(r),(s)Observed trash debris around the dumpster area. Refuse, recyclables, and returnables shall be removed from the premises at a frequency that will minimize the development of objectionable odors and other conditions that attract or harbor insects and rodents. (C)

Corrective Actions: PIC had dumpster area cleaned.

Violation #12:

17C: .07(5)(a),(b)1,2,3Observed the following; 1. food debris on the walk-in-cooler flooring 2. grease build up on the flooring in between the grill and the food contact table. 3. An accumulation of water under the kitchen flooring. All physical facilities shall be maintained in good repair and shall be cleaned as often as necessary to keep them clean and by methods that prevent contamination of food products. (C)

Additional remarks:

Cold-Holding was assessed and incompliance unless noted in the temperature log.

Hot-Holding was assessed and incompliance unless note in the temperature log.

additives= various flavored drink syrups

A follow-up is required within 10 calendar days; 8/29/24

U ON FOLLOW-UP MAY RESULT IN PERMIT SUSPENSION.

A Required additional routine inspection is required within 12 months (8/29/25)

Fees will be charged accordingly for any violation which cannot be corrected on-site during inspection.

Repeat violations may result in permit suspension.

Corrections of violations does not change the inspection score.