Remove ads by Supporting Independent News

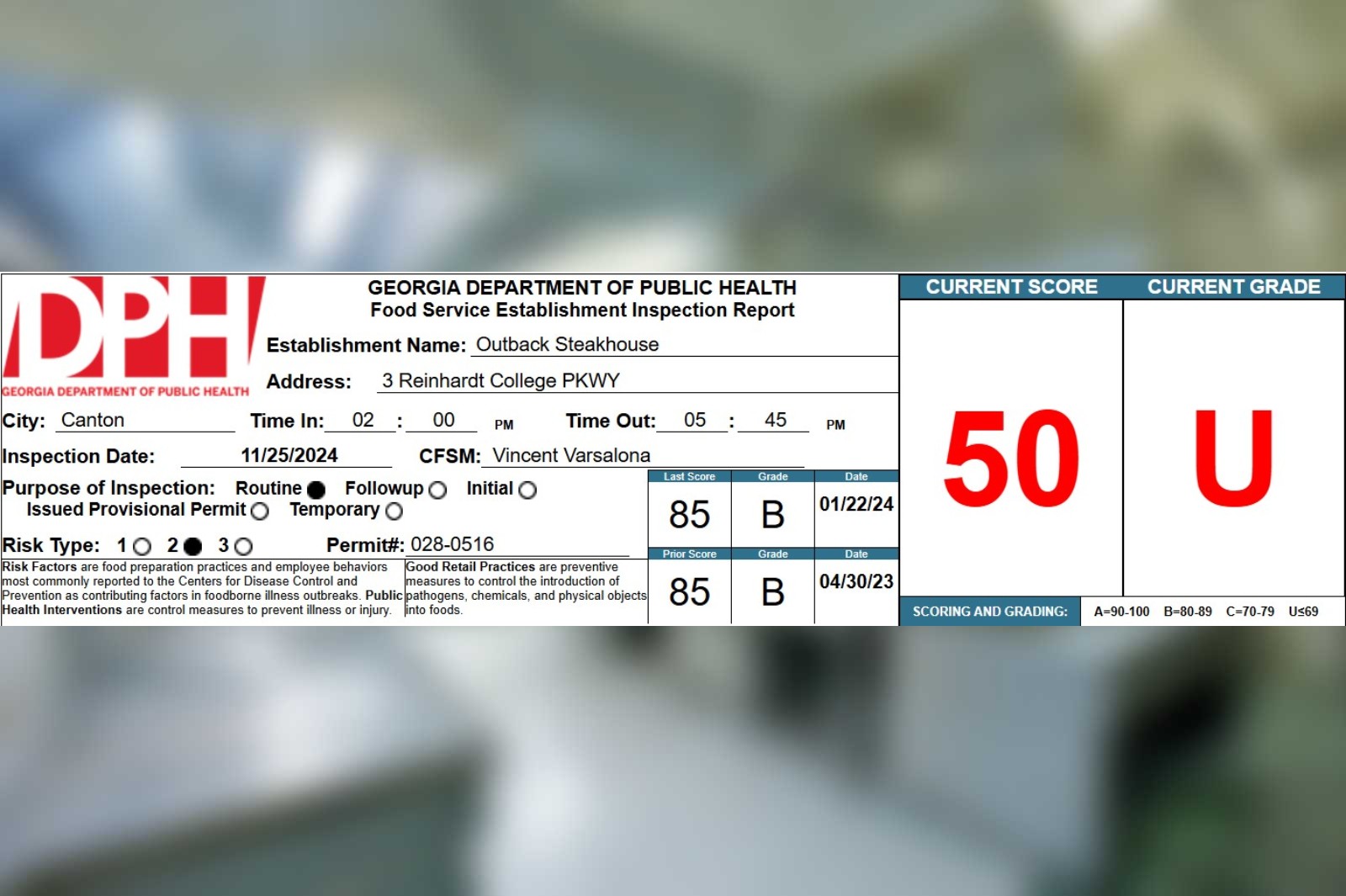

Outback Steakhouse, located at 3 Reinhardt College Pkwy in Canton, received a score of 50 points out of a possible 100 points during their 11/25/2024 inspection by the Georgia Department of Public Health.

The violations noted by the inspector were:

Violation #1:

2-1C – no bare hand contact with ready-to-eat foods or approved alternate method properly followed

511-6-1.04(4)(a)1,2,3,4(i) – preventing contamination from hands (p), (pf), (c)

Points: 9

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed kitchen employee handling ready-to-eat food (RTE) (cheese) with bare hands. Employee placed cheese on burger to melt however, cheese is not getting heated to a high enough temperature to kill any potential pathogens on hands. There may be no bared hand contact with RTE foods. COS by discarding and starting order over.

Violation #2:

4-1A – food separated and protected

511-6-1.04(4)(c)1(i)(ii)(iii)(v)(vi)(vii)(viii) – packaged & unpackaged food separation, packaging, and segregation (p, c)

Points: 9

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed improper vertical storage of raw meats in in 3 different coolers. There was two different sauces stored above raw beef in steak cooler, there was cheese sauce and alfredo stored above raw lobster in cooler to left of steak cooler, and raw hamburger patties stored above raw pork in walk-in (this was noted on previous inspection but not corrected). Raw meats must be stored based on final cook temperature and RTE sauces must be above all raw meat/seafood items. COS by properly storing.

Violation #3:

4-1A – food separated and protected

511-6-1.04(4)(n)1 – gloves, use limitation (single use gloves) (p)

Points: 9

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed employee handling raw beef with bare hands and failing to remove gloves prior to switching tasks. Employee went on the contaminated many surfaces and burger buns. COS by discarding buns. Must sanitize contaminated surfaces.

Violation #4:

4-2B – food-contact surfaces: cleaned & sanitized

511-6-1.05(6)(l) – mechanical warewashing, hot water sanitization temperatures(p)

Points: 4

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed high-temp dish machine not reaching minimum final rinse temperature of 160°F. Employee was actively using machine and only reached 149.5°F on the first check. Machine reached 160°F on second check. Must closely monitor machine as it has had issues in the past. Must also get new temperature stickers that reflect temperature reaching at least 160°F. The current stickers onsite are for 180°F.

Violation #5:

4-2B – food-contact surfaces: cleaned & sanitized

511-6-1.05(7)(b) – food contact surfaces and utensils – cleaning frequency (p, c)

Points: 4

Corrected during inspection?: No

Repeat: No

Inspector Notes: Observed kitchen employee temping food without first sanitizing thermometer probe before and after. 511-6-1.05(7)(b) – Food Contact Surfaces and Utensils – Cleaning Frequency (P, C) (b) Equipment Food-Contact Surfaces and Utensils. 1. Equipment food-contact surfaces and utensils shall be cleaned: (iv) Before using or storing a food temperature measuring device. Alcohol pads are kept in office but must be kept on cook line so that they are easily accessible to staff.

Violation #6:

4-2B – food-contact surfaces: cleaned & sanitized

511-6-1.05(7)(a)1 – equipment, food-contact surfaces,& utensils (pf)

Points: 4

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed four or five ladles and spoons stored on hook as clean but very visibly dirty with stuck-on food. PIC must ensure that employees are inspecting dishes when they come out of dish machine. Health Authority recommends doing a pre-soak/pre-wash to help loosen the stuck-on food prior to running through dish machine. COS by rewashing.

Violation #7:

4-2B – food-contact surfaces: cleaned & sanitized

511-6-1.05(7)(a)1 – equipment, food-contact surfaces,& utensils (pf)

Points: 4

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed two in-use knives stored in between equipment on cook line. These utensils must be stored in a clean, dry area and in a manner that prevents contamination. COS by rewashing.

Violation #8:

5-1B – proper reheating procedures for hot holding

511-6-1.04(5)(h) – reheating for hot holding (p)

Points: 9

Corrected during inspection?: Yes

Repeat: Yes

Inspector Notes: Observed prime rib prepared 11/21/24 not reheated to required temperature within allotted time. Prime rib began reheating at 2PM and was temping 77°F two hours later. Remaining unsliced portions of meat roasts that are cooked as specified under subsection (5)(a)2 of this Rule may be reheated for hot holding using the same oven parameters and minimum time and temperature conditions under which it was cooked. Must reheat prime rib to 130°F and hot hold at same temperature. COS by discarding. NOTE: This is a repeat violation from previous inspection. Health Authority recommends discontinuing this process for prime rib and only using for same day service to eliminate the reheat step.

Violation #9:

6-1A – proper cold holding temperatures

511-6-1.04(6)(f) – time/temperature control for safety; cold holding (p)

Points: 9

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed time/temperature control for safety (TCS) foods in prep top/ reach-in unit (between flat top and oven). All raw seafood and chicken in unit ranged between 47-52°F. TCS foods must be cold held at 41°F or below. COS by moving to another unit. Do not store TCS foods in unit until minimum cold holding temperature can be maintained.

Violation #10:

8-2B – toxic substances properly identified, stored, used

511-6-1.07(6)(g) – chemical sanitizers, criteria (p)

Points: 4

Corrected during inspection?: Yes

Repeat: No

Inspector Notes: Observed Sink and Surface (lactic acid) sanitizer dispensing too high. Required concentration for this sanitizer is 704-1875 ppm. However, sanitizer was dispensing at 3010 ppm. COS by diluting to 704 ppm.

Violation #11:

11A – proper cooling methods used: adequate equipment for temperature control

511-6-1.04(6)(e) – cooling methods (pf, c)

Points: 3

Corrected during inspection?: Yes

Repeat: Yes

Inspector Notes: Observed improper cooling methods being used for pasta. Pasta was cooling in large, deep container in walk-in and stored covered. CFSM stated that pasta was cooled to 41F on ice bath but was temping 57F in walk-in. 1. Cooling shall be accomplished in accordance with the time and temperature criteria specified under DPH Rule 511-6-1-.04(6)(d) by using one or more of the following methods depending on the type of food being cooled: (i) Placing the food in shallow pans; Pf (ii) Separating the food into smaller or thinner portions; Pf (iii) Using rapid cooling equipment; Pf (iv) Stirring the food in a container placed in an ice water bath; Pf (v) Using containers that facilitate heat transfer; Pf (vi) Adding ice as an ingredient; Pf or (vii) Other effective methods. Pf 2. When placed in cooling or cold holding equipment, food containers in which food is being cooled shall be: (i) Arranged in the equipment to provide maximum heat transfer through the container walls; and (ii) Loosely covered, or uncovered if protected from overhead contamination during the cooling period to facilitate heat transfer from the surface of the food. COS by moving pasta back to ice bath to cool. Facility may also consider utilizing a sheet tray to cool pasta and hold in walk-in cooler or freezer.

Additional remarks:

*Must keep food in prep top units covered while not in active use. Raw chicken was 44F but all other TCS foods in reach-in unit were well below 41F.

*Do not cool recently prepped foods in prep top units as it makes it more difficult to cool. Boiled eggs were 45F and tomatoes were 48F. All other foods were in temp.

*Must have some type of verification salmon is farm-raised since offered less than well. Must provide invoice that states this OR provide label on box OR letter from supplier

*EHP in place

**Reinspection within 10 days. Please focus on training staff on the the areas marked out of compliance on report. Health Authority can assist in training staff/management if desired–if so, don’t hesitate to reach out.